PCBA Processing, Do You Really Understand It? – A Practical Article to Answer All Your Questions

In today’s rapidly evolving electronics industry, PCBA (Printed Circuit Board Assembly), as the core component of electronic products, plays a crucial role. However, for many companies or individuals who are new to PCBA processing, it’s natural to have questions:

1. What exactly does PCBA processing include?

2. How to choose a reliable PCBA processing manufacturer?

3. How is the price of PCBA processing calculated?

4. How to ensure the quality and delivery time of PCBA processing?

Don’t worry, this article will answer all your questions one by one!

1. PCBA Processing Is Not Just Soldering!

Many people think that PCBA processing simply involves soldering components onto a PCB board. However, this is not the case. A complete PCBA processing workflow typically includes the following steps:

1. PCB Board Manufacturing: Producing the PCB board that carries the components based on the designed circuit diagram.

2. Component Procurement and Inspection: Purchasing components according to the BOM list and conducting strict incoming quality control to ensure component quality.

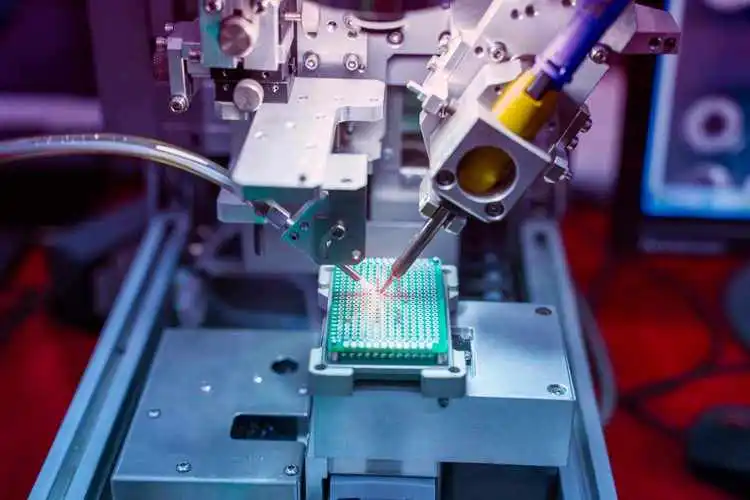

3. SMT Mounting: Using a pick-and-place machine to accurately mount miniature components onto the PCB board.

4. DIP Insertion: Installing larger components that cannot be handled by the SMT machine manually or through automated insertion.

5. Soldering: Using reflow soldering, wave soldering, or other techniques to firmly solder the components onto the PCB board.

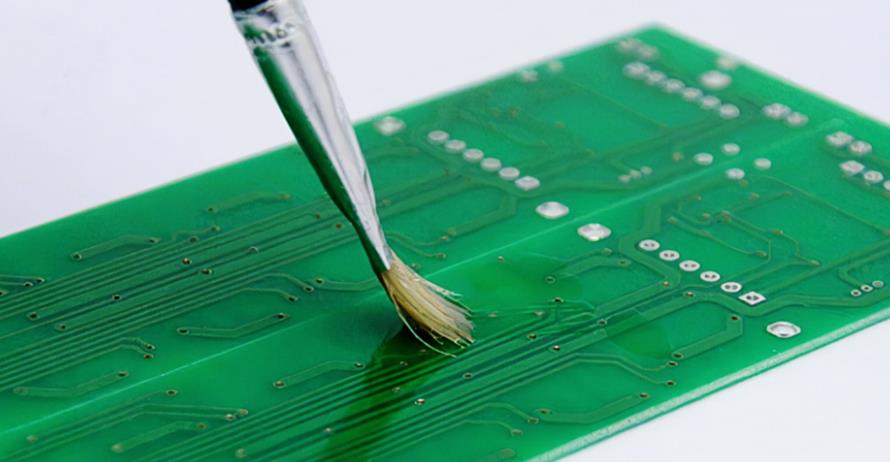

6. Cleaning: Removing residues generated during the soldering process to ensure the cleanliness of the PCBA board.

7. Testing: Conducting functional and performance tests on the PCBA board to ensure it meets design requirements.

8. Conformal Coating (Optional): Applying a protective coating based on the product’s operating environment to enhance its waterproof, moisture-proof, and anti-corrosion properties.

9. Assembly and Packaging: Assembling the PCBA board with other components and performing final packaging.

2. Choosing a PCBA Processing Manufacturer – Be Careful!

With so many PCBA processing manufacturers on the market, how do you choose a reliable partner? Here are some points to consider:

1. Certifications: Check if the manufacturer has certifications such as ISO9001 and other relevant industry qualifications.

2. Equipment and Technology: Evaluate whether the manufacturer has advanced equipment and a professional technical team capable of handling complex processes.

3. Quality Control: Understand the manufacturer’s quality control processes and whether they have established a comprehensive traceability system.

4. Delivery Guarantee: Assess the manufacturer’s production capacity to ensure they can complete orders on time and with quality.

5. Service Attitude: During communication, gauge the manufacturer’s service attitude and professionalism to see if they can respond to your needs promptly.

3. What Factors Affect PCBA Processing Prices?

The price of PCBA processing is not fixed and is influenced by the following factors:

1. PCB Board Complexity: The more layers, the smaller the trace width and spacing, and the higher the process requirements, the higher the price.

2. Component Types and Quantity: The more types and quantities of components, the higher the procurement and processing costs.

3. Processing Techniques: Different techniques, such as standard soldering, selective soldering, and conformal coating, have different costs.

4. Order Quantity: Larger order quantities usually result in lower unit prices.

5. Delivery Requirements: Rush orders typically incur additional expedited fees.

4. How to Ensure the Quality and Delivery Time of PCBA Processing?

1. Provide Complete and Accurate Technical Documentation: Including Gerber files, BOM lists, and assembly drawings to ensure the manufacturer fully understands your requirements.

2. Maintain Close Communication with the Manufacturer: Regularly update on project progress and resolve technical issues to avoid misunderstandings and delays caused by information asymmetry.

3. Implement Strict Incoming Inspection and Process Control: Monitor key components and critical processes to ensure product quality.

4. Establish a Comprehensive Quality Traceability System: Quickly identify the root cause of any issues and take corrective actions promptly.

Conclusion

Choosing a professional and reliable PCBA processing manufacturer is key to ensuring product quality and project success. We hope this article helps you better understand PCBA processing and find the right partner to create high-quality electronic products together!

Our company has been specializing in PCBA processing for many years. With advanced production equipment, a professional technical team, and a comprehensive quality management system, we are committed to providing high-quality and efficient PCBA processing services. If you have any needs, please feel free to contact us!

Tags: PCBA /Printed Circuit Board Assembly /

Prev: What Are the Types of PCB? Advantages, Disadvantages, and Applications of Different PCB Types

Next: PCBA Full Analysis: Industry Expert Answers Your Questions