PCBA Full Analysis: Industry Expert Answers Your Questions

Author: Tiger Wang, Senior Electronics Engineer at Newei Industrial, with 12 Years of PCBA Manufacturing Experience

As an electronics engineer specializing in the automotive and smart device industries for a decade, I often hear customers ask during PCBA (Printed Circuit Board Assembly) production optimization at Newei Industrial: What exactly is PCBA? How can quality be ensured? Why does delivery take so long? Drawing from my hands-on experience and industry insights, I will address these questions one by one to help you smoothly advance your projects.

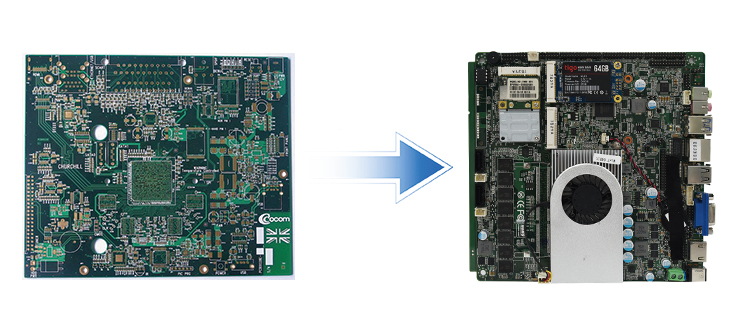

What Is PCBA? How Is It Different from PCB?

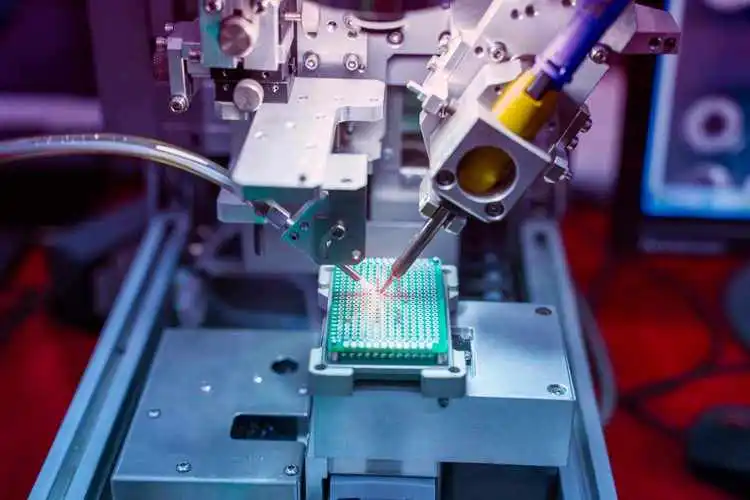

Having assembled countless circuit boards, I’m very familiar with this question. Simply put, PCB (Printed Circuit Board) is just a "bare board"—a substrate with copper foil traces. PCBA, on the other hand, is a functional module where electronic components such as resistors, capacitors, and chips are mounted onto the PCB using Surface Mount Technology (SMT) or through-hole soldering. For example, I once turned a blank PCB into a working PCBA for a medical device in just 48 hours. To illustrate, PCB is like a canvas, while PCBA is the finished artwork that directly powers your product.

Why Does PCBA Quality Vary?

After testing circuit boards from dozens of suppliers, I’ve found that quality differences mainly stem from three factors:

- Material Selection – High-quality PCBA uses RoHS-compliant lead-free solder and durable FR4 substrates. I once rejected a batch of defective boards because their poor-quality solder failed after 500 thermal cycles.

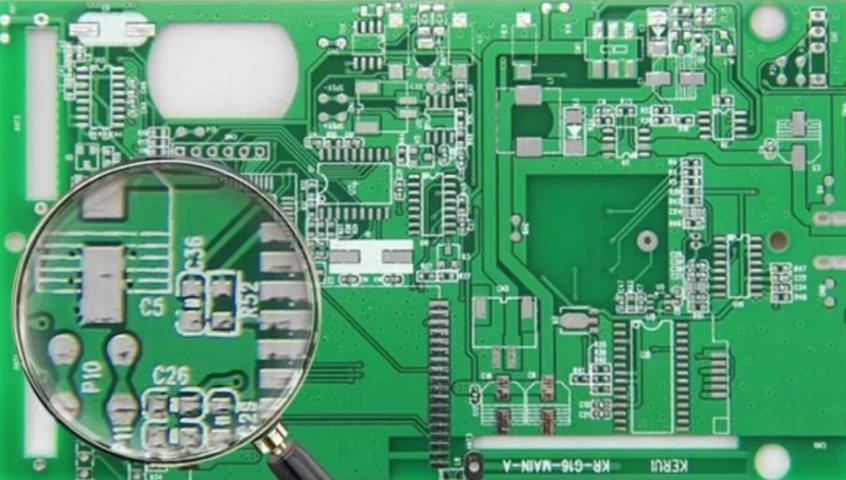

- Manufacturing Process – Advanced factories employ AOI (Automated Optical Inspection) and X-ray inspection. At Newei Industrial, these technologies helped reduce defect rates by 15% (based on 2024 internal data).

- Professional Expertise – Experienced teams can identify design flaws in advance. I once adjusted a layout to prevent solder bridging, saving the client significant rework costs.

I recommend choosing ISO 9001-certified suppliers—I have personally verified their reliability—and always requesting test samples. Quality is not a gamble; it’s a matter of technical assurance.

Why Does PCBA Delivery Take So Long?

Clients often ask, "Can it be faster?" As a production manager, I know delays mainly arise from three factors:

- Design Issues – Last month, a client submitted an incomplete Gerber file, delaying the project by a week.

- Component Procurement – Some specialized chips take 8-12 weeks to arrive, especially during the current chip shortage (see the 2024 SIA Semiconductor Report).

- Production Scheduling – Small orders are often delayed during peak seasons. I’ve seen this happen frequently during holiday rush periods.

My advice? Submit complete design files early and let suppliers stock commonly used materials. I once shortened delivery time by 30% by pre-ordering capacitors.

How to Control PCBA Costs?

Cost is a frequent concern. Based on my project experience:

- Optimize Design – I once reduced a 6-layer board to 4 layers, cutting costs by 20% without affecting functionality.

- Increase Order Quantity – Scaling up from 100 to 1,000 units can lower unit prices by 35%.

- Source Locally – Using local suppliers avoids import tariffs. I often apply this strategy in Asian projects.

But don’t just chase low prices—poor-quality boards fail quickly. I always advise balancing durability and cost.

What If PCBA Has Issues?

Even with strict inspections, failures can occur. Last year, a board short-circuited due to moisture exposure during shipping. My approach:

- Troubleshooting – Using a multimeter and thermal imaging, I pinpointed the issue with 95% accuracy.

- Rework – If the defect is a production error, repairs are usually free—it’s an industry standard.

- Preventative Measures – I advised the client to add a protective coating, permanently solving the problem.

When selecting a supplier, check if they offer 24/7 technical support like Newei Industrial and review their past projects.

Why Trust Me?

I am Tiger Wang, a Senior Engineer at Newei Industrial with 12 years of PCBA manufacturing experience. I have led projects for Fortune 500 clients and hold SMT and Lean Six Sigma certifications. My advice is based on real-world experience, not just theory. Want to learn more? Visit Newei Industrial’s case study page or email me at tiger.wang@richitek.com.

Conclusion

PCBA is the core of your product, and understanding it can determine your project’s success. With my expert guidance, you can confidently choose quality, control costs, and tackle challenges. Ready to get started? Let’s turn your ideas into reality!

Disclaimer: The examples provided are based on comprehensive project data. For personalized solutions, consult a professional PCBA engineer.

Tags: PCBA /PCB Assembly /PCBA Factory /

Prev: PCBA Processing, Do You Really Understand It? – A Practical Article to Answer All Your Questions

Next: Neway Industry Showcases One-Stop PCBA Solutions at 2025 ITES Shenzhen Industrial Exhibition