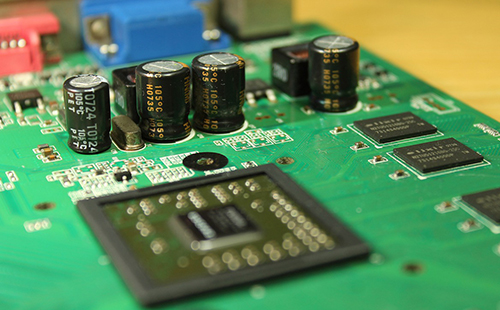

Our DIP plugin processing capability

Plug in AOI for component error, leakage, and reverse detection, strictly controlling DIP passthrough rate

Proficient blacksmith who receives strict training, with controllable welding speed and quality

According to the status of the circuit board, a temporary storage area with independent identification should be provided around the cable: waiting for plug-in, waiting for maintenance, waiting for QC inspection, defective products, waiting for QA inspection, etc., to avoid mixed boards

Strict IPQC and QA LOT sampling standards ensure the reliability of DIP processing