What should be noted when making PCBA cross-border samples?

PCBA cross-border sampling is a complex process involving multiple links and factors. To ensure the smooth progress of sampling and product quality, the following are some things to pay attention to:

1、 Choose the appropriate PCB manufacturer

Technical strength: Choose PCB manufacturers with advanced technology and rich experience to ensure that high-quality circuit boards can be produced according to design requirements.

Production capacity: Consider the manufacturer's production scale and capacity to ensure timely delivery of sample products.

Quality control: Understand the manufacturer's quality control system to ensure that products meet quality requirements.

Reputation and word-of-mouth: By conducting online searches, consulting with peers, and other means, we can understand the reputation and word-of-mouth of manufacturers and choose reputable ones for cooperation.

2、 Confirm circuit diagram design

Design rationality: Before cross-border sampling, it is necessary to confirm whether the circuit diagram design is reasonable, including circuit schematic, PCB layout, component list, and other aspects.

Compatibility: Consider electrical standards and specifications from different countries and regions to ensure that circuit designs meet the requirements of the target market.

3、 Component procurement

Model and specifications: Confirm whether the model and specifications of the components used are correct, and consider the supply situation of components in different countries and regions.

Performance and characteristics: Understand the performance and characteristics of components to ensure compliance with design requirements.

Supplier selection: Choose reliable component suppliers to ensure the quality and supply stability of the components.

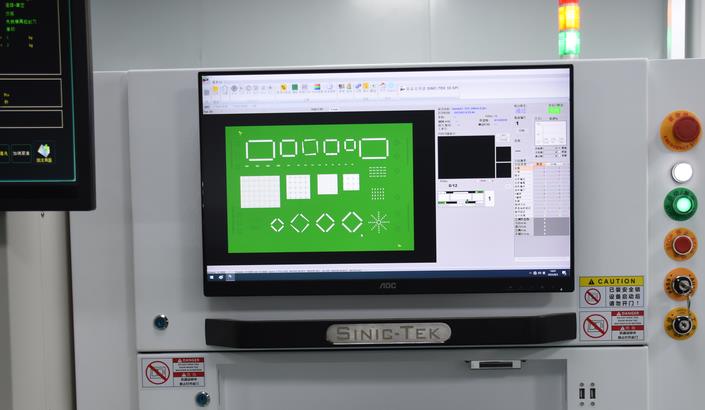

4、 PCB process flow

Board selection: Select appropriate PCB boards according to design requirements to ensure the performance and reliability of the circuit board.

Printing process: Understand the different steps of PCB printing process, such as photolithography, etching, metalization, etc., and choose the suitable process flow for the target market.

Surface treatment process: Select appropriate PCB surface treatment processes according to design requirements, such as electroplating, tin spraying, hot air leveling, etc.

5、 Quality control

Raw material procurement: Select high-quality raw material suppliers and strictly control their quality.

Production process monitoring: Real time monitoring and recording of the production process to promptly identify and resolve issues.

Quality inspection and testing: Conduct strict quality inspection and testing on PCBA products to ensure that they meet design requirements and quality standards.

6、 Communication and feedback

Strengthen communication and feedback between the design team, manufacturer, and testing team to ensure timely transmission of information and resolution of issues.

Promptly identify problems and provide feedback to the design team, optimize and improve them accordingly to improve the performance and quality of the circuit board.

7、 Logistics and Delivery

Choose a reliable logistics company for cross-border transportation to ensure timely delivery and good condition of products.

During the delivery process, pay attention to the packaging and protection of the product to ensure that it is not damaged during transportation.

8、 Legal regulations and standards

Understand and comply with the laws, regulations, and standards of the target market to ensure that the product meets the requirements of the local market.

Pay attention to intellectual property issues and ensure that the intellectual property rights of others are not infringed upon during the cross-border sampling process.

PCBA cross-border sampling requires attention to multiple aspects, including selecting a suitable PCB manufacturer, confirming circuit diagram design, component procurement, PCB process flow, quality control, communication and feedback, logistics and delivery, as well as laws, regulations and standards. Only by comprehensively considering these issues and taking corresponding measures can we ensure the smooth progress of PCBA cross-border sampling and product quality.

Tags: PCBA /cross-border /

Prev: What is the largest PCB company in the world?

Next: What is the testing principle of PCBA?