What is the difference between ICT and FCT in PCBA testing?

PCBA testing is a crucial step in ensuring the quality of shipments. Generally, customers need to provide a testing plan, including testing points, procedures, testing steps, etc. PCBA electronic manufacturers perform corresponding ICT and FCT tests based on design documents. ICT (In circuit test) is mainly aimed at the component level. By contacting the pins of each component on the PCBA board, it measures whether their values match the nominal values. It is a very important means to detect the values and polarity of components such as resistance, capacitance, and inductance.

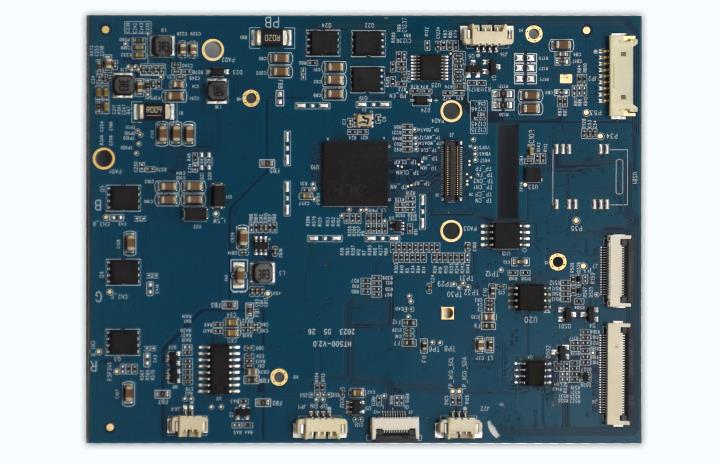

However, with the rapid development of process capability in the electronics industry, ICT testing has become increasingly scarce, as many components can achieve quality below 50PPM, fully meeting the process yield of electronic products. At this point, FCT (Function Test) becomes particularly important. The PCBA manufacturer will issue an FCT test stand based on the design documents, place the PCBA board on the test stand, capture the test points on the PCBA board, write programs through a burner, and then simulate the input and output actions of the product to achieve the testing purpose. In some cases, upper computer software is also needed for coordination. FCT testing is a functional testing approach close to the product level, which can effectively cover the performance range of the product and is a very effective means.

Tags: ICT /FCT /PCBA_testing /

Prev: What is the testing principle of PCBA?

Next: Answers to questions regarding NEWEI PCBA sampling, confidentiality, transportation, pricing, etc