What are the methods of PCBA process control?

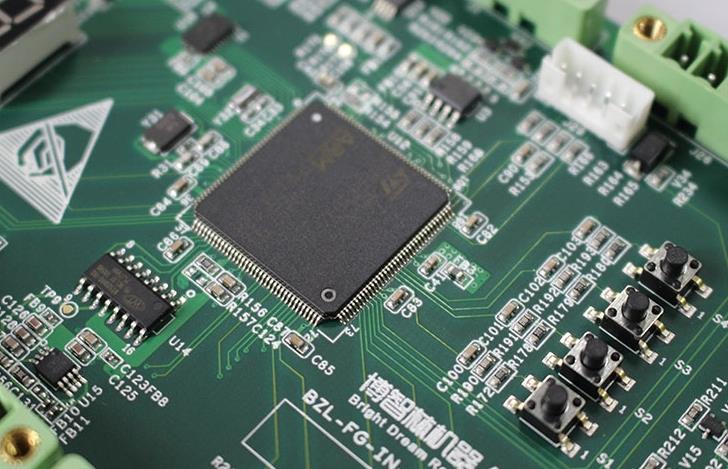

There are many production processes in PCBA, and to ensure the quality of PCBA processing, professional process control methods and tools are needed for control. Especially when producing high-end products, PCBA process control is even more necessary to produce products that meet customer requirements.

1、 IPQC process control

During the PCBA production process, a PCBA process control position, commonly known as an IPQC position, can be set up. The main responsibilities of IPQC include:

Check if all assembly processes and surface mount components comply with the IPC-A-610D standard;

Operation manual and automatic inspection of the entire PCBA process;

Ensure consistency in the electronic assembly process;

Significant deviations in management statistical methods and techniques;

Arrange a specialist to audit standard procedures and identify process improvement needs.

2、 PDCA and SPC

PCBA process control can also be controlled through tools such as PDCA mode and SPC statistical process control.

Process is a fundamental element of the quality management system, and studying the interrelationships and interactions between processes provides a clear idea for managing quality activities in the system, which is more conducive to effective and continuous control of many processes. The operation (control) of each process follows the PDCA cycle mode.

1. P (Plan) - Plan, determine policies and objectives, and determine activity plans;

2. D (Do) - Execute, do it on-site, and achieve the content of the plan;

3. C (Check) - Check, summarize the results of the execution plan, pay attention to the effectiveness, and identify problems;

4. A (Action) - Take action, process the results of summary checks, affirm successful experiences, and appropriately promote and standardize them; Summarize the lessons of failure to avoid recurrence, and place unresolved issues in the next PDCA cycle.

SPC: Statistical Process Control (SPC) is a tool for process control that applies statistical methods to evaluate and monitor various stages of the process in order to implement the principle of prevention. It establishes and maintains an acceptable and stable level of the process, thereby ensuring that products and services meet regulatory requirements.

With the increasing difficulty of electronic product processing, process control of PCBA has become increasingly important as a means to improve quality.

Tags: PCBA /process_control /

Prev: What does DFM mean? What is the significance of PCBA DFM?

Next: What are the steps of PCBA cleaning method?