What services do PCB assembly manufacturer generally provide?

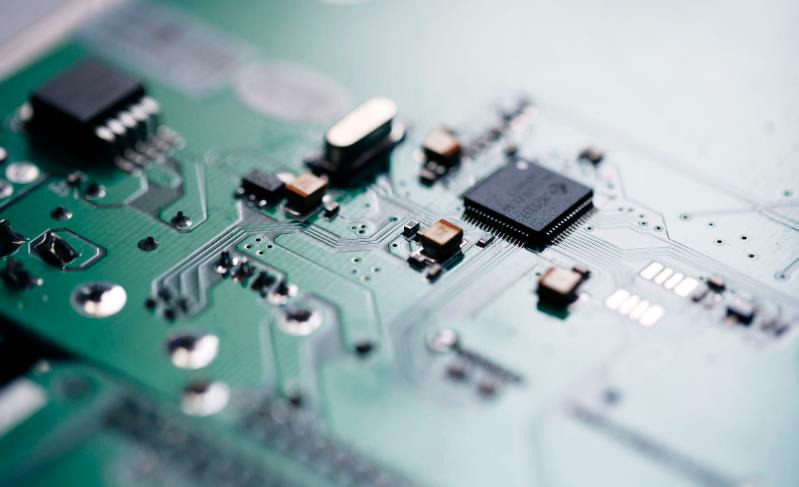

A PCB Assembly Manufacturer typically offers the following services:

PCB Fabrication: They can fabricate PCBs based on customer-provided PCB drawings. This includes PCB design consultation services as well.

Electronic Components Sourcing: For PCBA manufacturers that also handle components procurement, they have a strong procurement team that ensures the quality of components while searching for the best prices.

SMT (Surface Mount Technology) Assembly: Using advanced SMT machines and skilled personnel, they provide high-quality SMT placement services.

DIP (Dual In-line Package) Insertion: For components that cannot be assembled using SMT, DIP insertion is used, which is also a service provided by PCBA manufacturers.

AOI (Automated Optical Inspection): After assembly, PCBA manufacturers conduct AOI to ensure the position, polarity, and adherence of each component meet the requirements.

Functional Testing: Once SMT and DIP assembly are complete, functional testing is performed to ensure the PCBA's performance meets the design specifications.

Conformal Coating (If Required): For boards that require conformal coating for protection, the manufacturer provides this service using automatic coating machines. The coating can be selectively applied to protect components like connectors, USB ports, and sensors.

Packaging and Shipping: After the assembly and testing are complete, the PCBAs are packaged and shipped to the customer.

In summary, a PCB Assembly Manufacturer provides a comprehensive range of services from PCB fabrication to component procurement, assembly, testing, coating (if required), and packaging/shipping.

Tags: PCB_assembly /PCB_assembly_manufacturer /

Prev: What are the cleaning solvents for the surface of PCBA circuit boards?

Next: What is the most difficult technical process for PCB assembly?