What is the most difficult technical process for PCB assembly?

In the PCB (Printed Circuit Board) assembly process, the technical difficulty can vary depending on the different processes and stages involved. However, based on the provided information, here are some perspectives on the most difficult technical processes for PCB assembly:

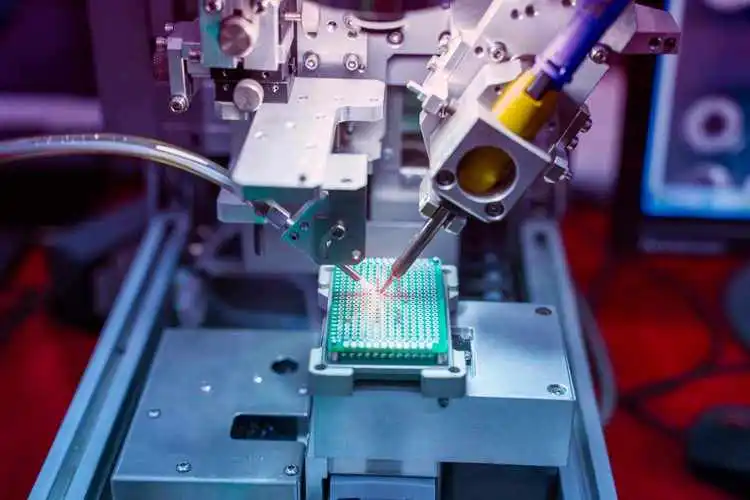

- Precise Component Placement:

- Accurate placement of components is a challenge in PCB assembly, especially when using Surface Mount Technology (SMT). This typically involves the use of pick-and-place machines that require precise programming to ensure each component is placed in the correct position. This process demands high precision and accuracy, as any slight deviation can lead to component malfunction or instability in the circuit board.

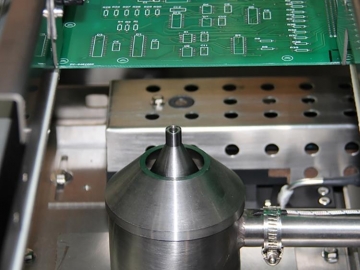

- Soldering Process:

- Soldering is a crucial step in fixing components to the PCB. It requires precise control over the application of solder paste, placement of components, and the temperature and duration of the soldering process. Improper soldering can result in open circuits, short circuits, or other electrical failures, affecting the overall performance of the circuit board.

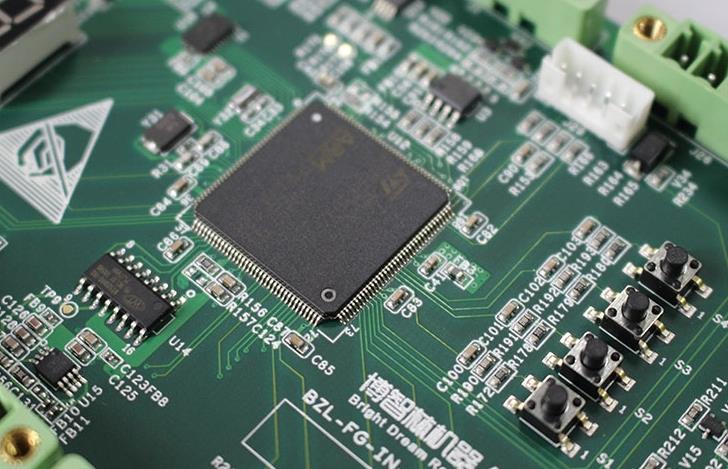

- Mixed-Technology Assembly:

- As circuit designs become more complex, mixed-technology assembly (using both Through-Hole Technology (THT) and Surface Mount Technology (SMT)) has become more prevalent in PCB assembly. This mixed-technology approach introduces greater complexity, as manufacturers must handle different types of components and connection methods on a single circuit board.

- Inspection and Correction:

- After component placement, the circuit board must undergo inspection and correction to ensure all components are properly in place. This process requires careful attention and patience, as any undetected errors can lead to failures in subsequent steps.

- Testing Phase:

- Although testing is not a direct technical process in assembly, it is crucial for ensuring the quality and stability of the PCB. Testing includes visual inspection, functional testing, performance testing, and environmental testing, which require expertise and experience to perform accurately.

The most difficult technical processes in PCB assembly can include precise component placement, the soldering process, mixed-technology assembly, inspection and correction, and the testing phase. These processes require high precision, accuracy, and expertise to ensure the quality and performance of the final product.

Tags: PCB_assembly /

Prev: What services do PCB assembly manufacturer generally provide?

Next: How to control the quality of PCB boards in PCB factories?