How to control the quality of PCB boards in PCB factories?

Quality is the foundation of a company's survival. If quality control is not in place, the company will not go far. If PCB factories want to control the quality of PCB boards, how should they control it?

To control the quality of PCB boards, we must have a quality control system, commonly known as ISO9001. The concept of a quality control system is real-time quality measurement and supervision. When there is a unified measurement and supervision standard for something, it is much easier to do it well.

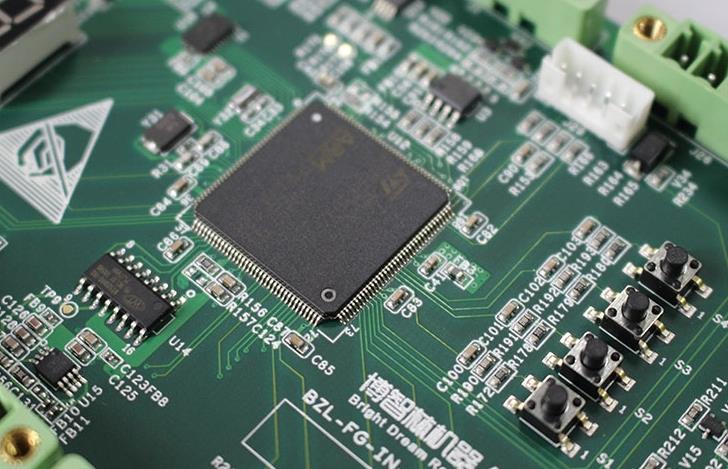

To control the quality of PCB boards, strict quality inspections should be conducted from the raw materials. Any defects found should be registered, reported, and solutions should be proposed in a timely manner. Only when the quality of the raw materials is guaranteed can high-quality PCB boards be obtained. If the quality of the raw materials is not guaranteed, the produced PCB boards are also likely to have various problems, such as blistering, delamination, cracking, board warping, and uneven thickness. So the raw materials must be strictly inspected to provide assurance for future production.

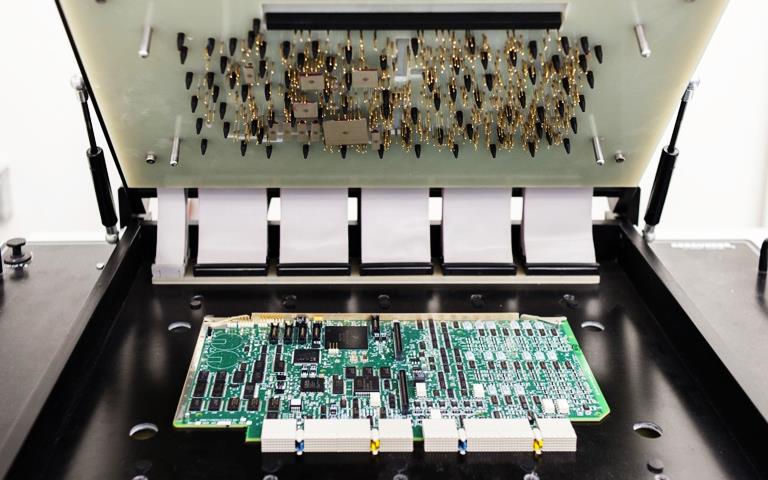

When the quality of raw materials is guaranteed, it is important to pay attention to the problems that may occur during the production process. Quality inspection and inspection should be carried out on every step of the production process to ensure that there is a work instruction book for each step, in order to facilitate comprehensive control of PCB quality.

After production is completed, spot checks must also be carried out. Although quality inspection has been carried out on the raw materials and production process, there may still be defects caused by various reasons. Therefore, the entire batch of PCB boards must be spot checked after production is completed. As long as the pass rate of the spot check meets the standard, it is allowed to leave the factory. If the pass rate of the spot check does not meet the standard, a full inspection and repair will be carried out, and the quality of each PCB board leaving the factory must be taken responsibility.

Tags: PCB_boards /PCB_factories /quality /

Prev: What is the most difficult technical process for PCB assembly?

Next: The basic requirements of SMT process for component layout design