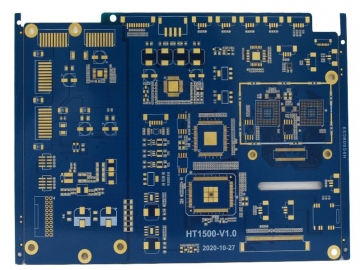

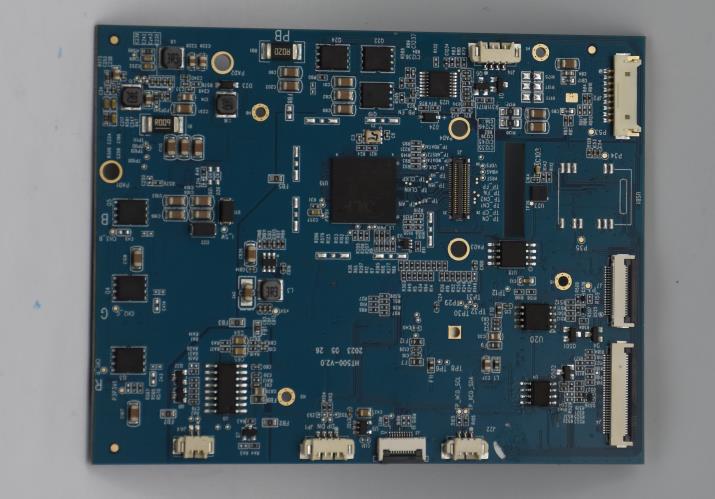

Management methods for MSL humidity sensitive components in PCBA processing

Many EMS electronic manufacturing factories often encounter humidity sensitive electronic components, which must be highly valued. Due to improper management of humidity sensitive components, it can directly lead to poor soldering, resulting in various defects such as false soldering, continuous soldering, and insufficient soldering. The management of humidity sensitive components is mainly carried out from two aspects: storage and feeding.

Each type of humidity sensor has its own MSL (Moisture Sensitivity Level), which clearly specifies the maximum allowable exposure time and feeding interval for humidity sensors. Once it exceeds its agreement, strict baking must be carried out before going live. Moisture sensitive components are generally stored in moisture-proof cabinets with specific functions. It is recommended to install specific temperature and humidity alarms on the moisture-proof cabinet to remind warehouse personnel that if the humidity exceeds the standard, an alarm and manual intervention will be triggered. When removing, it is necessary to check the condition of the humidity label card and record the removal time and the return time of the remaining materials.

MSL has 8 levels of classification

Level 1- Infinite workshop life less than or equal to 30 ° C/85% RH

Level 2- workshop life less than or equal to 30 ° C/60% RH for one year

Level 2a - Less than or equal to 30 ° C/60% RH four week workshop life

Level 3- workshop life less than or equal to 30 ° C/60% RH 168 hours

Level 4- workshop life less than or equal to 30 ° C/60% RH 72 hours

Level 5- workshop life less than or equal to 30 ° C/60% RH for 48 hours

Level 5a - workshop life less than or equal to 30 ° C/60% RH for 24 hours

Level 6- workshop life less than or equal to 30 ° C/60% RH for 12 hours (for Level 6, components must be baked before use and must be refluxed within the time limit specified on the moisture sensitive label)

The process of MSL determination is:

(1) Good quality IC undergoes SAT to confirm that there is no delamination phenomenon.

(2) Bake the IC to completely eliminate moisture.

(3) Humidify according to MSL level.

(4) Go through IR Reflow 3 times (simulate IC loading, repair disassembly, repair re loading).

(5) SAT inspection for delamination and IC testing function.

If the above test can be passed, it indicates that the IC packaging meets the MSL level.

Generally speaking, factories will establish strict forms that require operators to conduct strict registration before each retrieval, inspection, and feeding to ensure the effectiveness of materials. The management of humidity sensitive components is a crucial operational requirement in the entire PCBA processing process, and strict management must be carried out.

Tags: PCBA /PCBA_processing /components /MSL /

Prev: What are the reliability tests in the PCBA processing process?

Next: What is DFX and what are the main contents of DFX