What is EMS PCB How to understand it in a simple and easy way?

EMS PCB refers to the manufacturing, assembly, testing, and related services of printed circuit boards (PCBs) within the context of electronic manufacturing services (EMS). To understand it simply, it can be viewed as a comprehensive production model that provides brand owners of electronic products with a full range of services from PCB manufacturing to system assembly.

EMS (Electronic Manufacturing Services):

Definition: EMS is a rising industry that provides manufacturing, procurement, partial design, and logistics services to electronic product brand owners.

Key Services: PCB assembly services, system assembly services, design and build services.

Application Areas: Computers, consumer electronics, aerospace and defense, healthcare, automotive, and communications.

PCB (Printed Circuit Board):

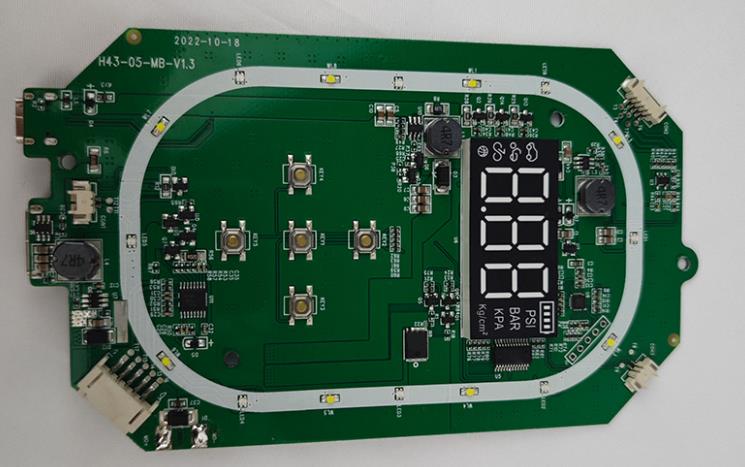

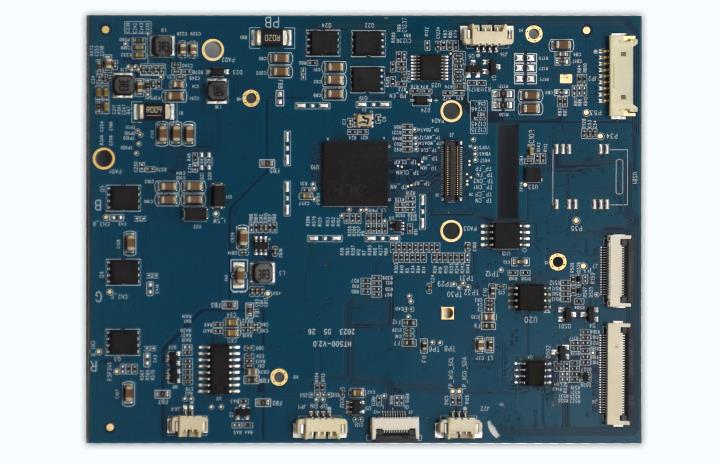

Definition: PCB is a carrier for the electrical interconnection of electronic components and one of the most important electronic components in the electronics industry.

Function: The performance of PCB directly determines the stability and reliability of the control circuit section.

Manufacturing Process: Involves steps such as solder paste printing, component placement, reflow soldering, manual soldering, and AOI inspection.

The association between EMS and PCB lies in the fact that PCB assembly is an integral part of the EMS services, where EMS providers cater to the manufacturing and production needs of electronic products for brand owners, including PCB-related services.

EMS (Electronic Manufacturing Services) and PCBA (Printed Circuit Board Assembly) play distinct roles in the electronics manufacturing industry, with their relationship and differences outlined below:

Relationship:

PCBA is actually a component of EMS. EMS is a broad concept that covers various aspects of electronic manufacturing services, from circuit board design and supply chain management to assembly, testing, and after-sales support. PCBA specifically refers to the assembly of electronic components onto manufactured printed circuit boards within these services.

Differences:

Scope and Service Content:

EMS: Provides comprehensive electronic manufacturing services, including raw material procurement, component testing, product packaging, and logistics distribution.

PCBA: Focuses on the assembly of printed circuit boards, including component placement, soldering, and related testing.

Scale and Expertise:

EMS: EMS companies are typically specialized electronic manufacturing service providers with large-scale manufacturing capabilities and professional expertise. They possess advanced equipment, professional engineering teams, and extensive manufacturing experience to meet clients' large-scale production demands.

PCBA: Can be provided by EMS companies or manufacturers specializing in PCBA. Compared to EMS companies, PCBA manufacturers are often smaller in scale but possess deeper expertise and experience in PCBA.

Customer Relationships:

EMS: EMS companies typically establish long-term partnerships with clients, becoming their strategic partners. They collaborate with clients based on customer requirements and design specifications, providing customized electronic manufacturing services from prototyping to mass production.

PCBA: PCBA manufacturers usually produce in batches based on client orders, focusing on providing high-quality PCBA assembly services. Client-PCBA manufacturer relationships are more focused on product requirements and technical specifications for circuit board assembly.

Technical Difficulty:

EMS: Compared to PCBA, EMS involves more complex and challenging processes, requiring a higher technical foundation. EMS covers the entire process from design to production, involving multiple technical aspects.

PCBA: Focuses on the assembly of printed circuit boards, requiring a certain technical foundation but with relatively lower technical difficulty compared to EMS.

EMS and PCBA play different roles in the electronics manufacturing industry. EMS provides comprehensive electronic manufacturing services, while PCBA is a component of EMS, specializing in the assembly of printed circuit boards. When understanding their relationship, it is important to note that PCBA is a crucial part of EMS, but EMS has a broader service scope.

Prev: Guidelines for rework and repair (electrical assembly repair, secondary welding) in PCBA processing

Next: What does quick turn printed circuit board mean How to understand?