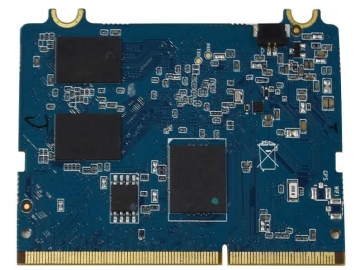

How important is ESD static protection during PCBA processing?

There are many precision electronic components on the PCBA board, and many components are sensitive to voltage. Shock higher than the rated voltage will damage these components. The PCBA board damaged by static electricity in the function of testing is difficult to gradually check. More fatal is that some PCBA board in the test when the function is normal, but the finished product in the hands of customers to use, but there are occasional bad, to bring great after-sales hidden danger, affecting the company's brand and goodwill. Therefore, PCBA processing must pay great attention to ESD static protection.

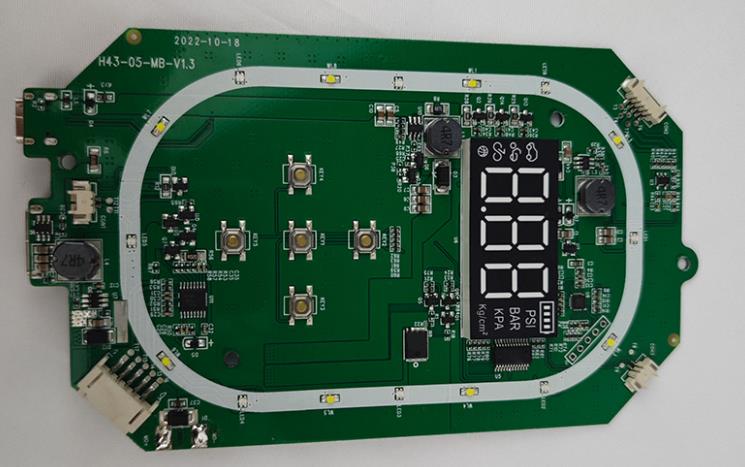

PCBA processing strict control of ESD electrostatic protection methods are generally as follows.

To ensure that the workshop temperature and humidity within the standard range, 22-28 degrees Celsius, humidity 40% -70%.

All employees in and out of the workshop must be electrostatic discharge

In accordance with the requirements of dress, wear static cap, wearing static clothes, static shoes

All need to touch the PCBA board workstation, must wear a corded electrostatic ring, the corded electrostatic ring into the electrostatic alarm

Separate the electrostatic line from the ground line of the equipment to prevent equipment leakage, resulting in damage to the PCBA board.

All turnover carts, electrostatic frames, shelves, etc. must be connected to the electrostatic ground line.

Strictly in accordance with ISO quality management requirements for ESD static electricity point inspection

Static electricity in the production process can not be seen and touched, God, often inadvertently on the PCBA circuit board has a fatal hidden danger, PCBA troubleshooting costs are very high. Therefore, each factory manager must pay strict attention to ESD electrostatic management, so that the PCBA process is a complete quality control.

Tags: PCBA /PCBA_processing /ESD /

Prev: What are the requirements for an excellent electronic PCB assembly manufacturer?

Next: Why has FCT replaced ICT in PCBA testing become a trend?