PCBA fast sampling process

PCBA sampling is PCBA mass production must be carried out before an important part of the sampling is the most important purpose is to verify whether the product design is reasonable, in order to minimize the cost of detecting the problem, for the subsequent mass production to save costs, often in the PCBA sampling, leaving engineers or product companies have little time, so in the sampling time will often require PCBA Processing plant to speed up the sampling schedule, hope to get the sample as soon as possible. General PCBA sampling time is required 7-14 days, and rapid sampling only 3-5 days to complete, then 3-5 days of PCBA rapid sampling is how to complete?

First of all, to ensure the accuracy of the Gerber file and BOM file, the delivery of longer components to replace the components can be immediately ordered to pick up the components, because the sampling is only a preliminary verification of the product design, so you can use the appropriate alternative materials to save sampling time, or in the sampling before the long cycle of material has been prepared and the supplier, and so to be sampling time directly pick up can be, this is also a common method to reduce the waiting time for materials. This is also a common method to reduce the waiting time for materials.

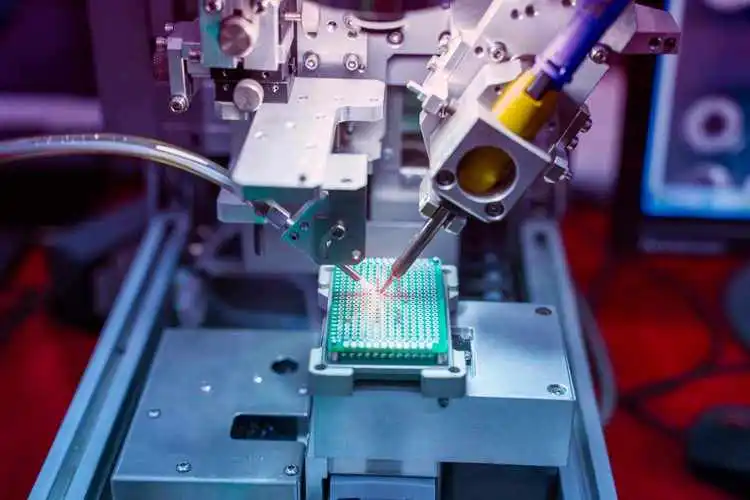

When all the materials are complete set, the rest of the production is actually a very fast thing, usually only need to spend 1-2 days of time to get it done, so summed up PCBA rapid prototyping process is: ready to prepare the information → choose the right alternative material → procurement → production → verification. In the process of doing PCBA rapid prototyping, you must know your purpose, grasp the big and small, in order to do PCBA rapid prototyping.

Tags: PCBA /fast_sampling /

Prev: What are the certifications for PCBA processing factories?

Next: Reflow soldering common quality defects and solutions