The relationship between electronic assembly technology and product quality

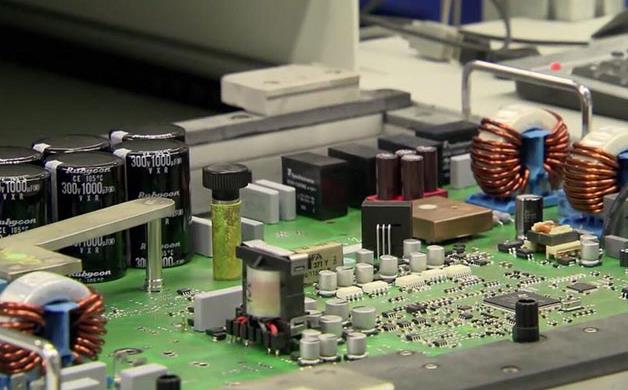

Electronic assembly technology is the basis of the electronic equipment manufacturing industry, electronic assembly welding is the core process; solder joints as a result of welding, the formation of electrical connection nodes of the degree of reliability of the equipment product performance and service life cycle has a greater impact. Even a simple circuit function module, the number of solder joints is far more than the number of components; the quality of each solder joint not only directly affects the electrical performance of the product, but also has a serious impact on the stability of the product's performance and the reliability of use. The failure of a solder joint may not only lead to components, components or electronic equipment products can not realize the expected function, and even lead to the failure of the entire large-scale system. Therefore, the quality of electronic assembly welding process has become a key factor affecting the reliability of electronic equipment.

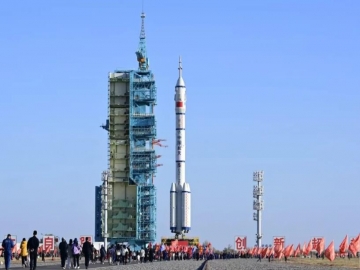

Research results show that: in the electronic machine product welding quality problems in about 75% is caused by the printed circuit board component solder joint failure. As a result of a large number of high-density packaging components and the application of new technologies, resulting in PCBA solder joint defects, detection and positioning difficulties, poor visibility and repairability, and even the consequences of unrepairable. In the electrical assembly and welding process, solder joint defects is an important factor directly affecting the quality of assembly, part of the defects in the inspection process is not easy to be found, especially most of the invisible "virtual welding" and part of the "cold welding" can only be found in the later debugging and use of the process. Only in the later debugging and use of the process will be found. Electronic products of electronic assembly welding quality is a systematic project, to solve this problem, neither on the matter, nor can we avoid the light. Electronic assembly welding quality issues related to the design of manufacturability, logistics quality, process optimization, management mode and personnel quality of five major aspects. We should not only grasp the main contradiction and the main aspect of the contradiction, but also pay great attention to the details, because "details determine success or failure". We must firmly establish the quality concept that no military product is trivial and no aerospace product is trivial! We must put forward requirements for the quality control of electronic products in the whole process of development and production from the four levels of manufacturability design, logistics, process optimization and quality monitoring, covering typical assembly and welding process types, new components, new materials, new technology applications and key process quality control requirements.

Combining design and process together, combining process and process control together, it puts forward the quality requirements and quality objectives of military electronic assemblies, as well as the design, material, process optimization and quality monitoring measures to achieve the above quality objectives.

Tags: electronic_assembly /technology /product_quality /

Prev: PCBA "three-proof" process design requirements explained

Next: What are the common chip component layout design flaws in PCBA manufacturing?