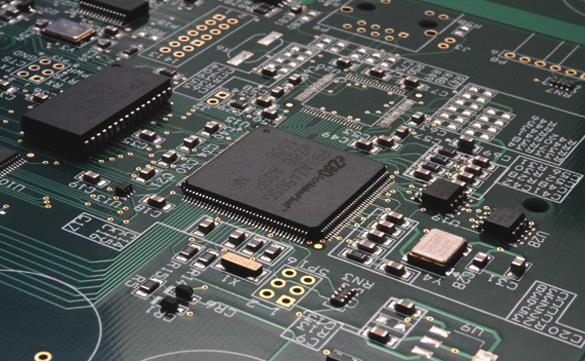

What are the common chip component layout design flaws in PCBA manufacturing?

Common chip component layout design flaws in PCBA manufacturing include:

Insufficient Spacing: Components are placed too close together, which can lead to solder bridging (short circuits) during the soldering process. This is especially problematic for components with fine pitch or small pad sizes.

Incorrect Component Orientation: Components are not oriented correctly on the PCB, which can cause issues with soldering, inspection, and functionality. Polarity-sensitive components must be oriented correctly to function properly.

Overlapping Components: Components are placed in such a way that they overlap or interfere with each other, making it difficult to solder or inspect them properly.

Insufficient Heat Dissipation: Components that require good heat dissipation are not properly placed to allow airflow or are located in high-heat areas, which can cause premature component failure.

Insufficient Grounding and Isolation: Lack of proper grounding and isolation of components can lead to noise, interference, and potential damage to sensitive components.

Inadequate Trace Widths and Routing: Trace widths are too narrow or routing is inefficient, causing signal degradation, heating, or reduced current-carrying capacity.

Use of Unsupported Components: Components are used that are not supported by the PCB design or manufacturing process, leading to soldering or placement issues.

Lack of Component Identification and Marking: Components are not properly labeled or marked, making it difficult to identify them during inspection, testing, or repair.

Poor Mechanical Stability: Components are not mounted securely or are subject to excessive stress, which can cause them to become dislodged or fail prematurely.

By identifying and correcting these common layout design flaws, PCBA manufacturers can improve the quality, reliability, and performance of their products.

Tags: PCBA /PCBA_manufacturing /layout /

Prev: The relationship between electronic assembly technology and product quality

Next: Can Vietnam overtake China in PCBA manufacturing?