What is PCBA? What is the difference between PCBA and PCB?

What is a PCBA circuit board and what is the difference from a PCB?

1) What is PCB and PCBA:

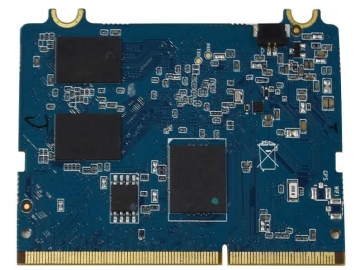

PCB -- Printed Circuit Board

PCBA - Printed Circuit Board+Assembly

2) Difference:

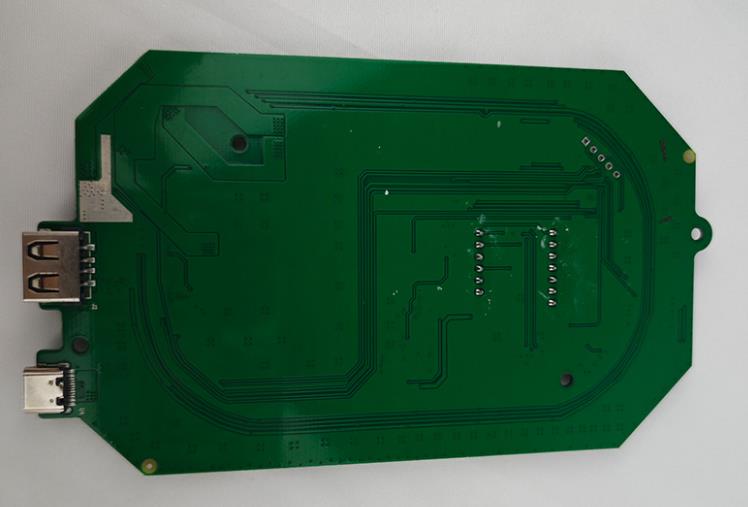

1. The PCB does not have any components

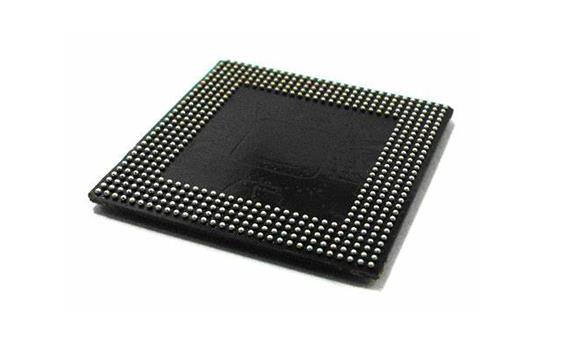

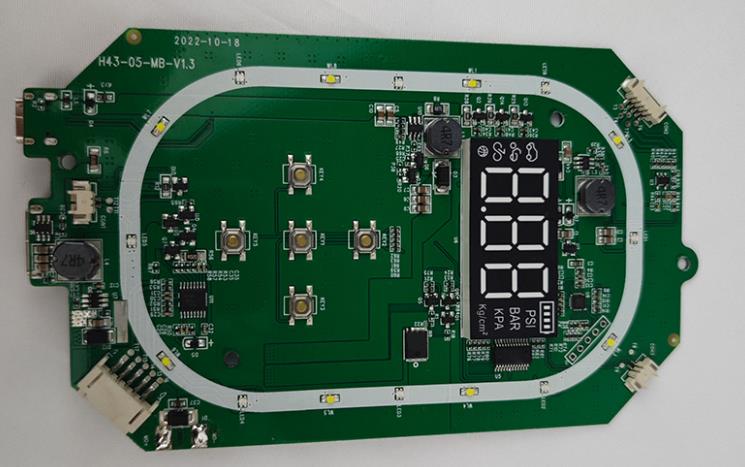

PCBA refers to the electronic components that manufacturers use SMT or plug-in processing to solder and assemble on the PCB board after receiving the PCB as raw material. For example, electronic components such as ICs, resistors, capacitors, crystal oscillators, transformers, etc. are heated by a reflow soldering furnace at high temperature to form a mechanical connection between the components and the PCB board, thus forming PCBA.

Tip: PCBA is the abbreviation for Printed Circuit Board+Assembly in English. Simply put, the entire process of PCB empty board passing through SMT mounting and then DIP plug-in is called PCBA. Simply put, PCB is a circuit board without mounting components, while PCBA is a circuit board soldered with electronic components.

PCB features:

1. High wiring density, small size, light weight, conducive to miniaturization of electronic devices.

2. Due to the repeatability and consistency of graphics, errors in wiring and assembly are reduced, saving equipment maintenance, debugging, and inspection time.

3. Beneficial for mechanized and automated production, it improves labor productivity and reduces the cost of electronic equipment.

4. Design can be standardized, facilitating interchangeability.

PCB is the abbreviation for Printed Circuit Board, which translates to printed circuit board in Chinese. Due to its use of electronic printing technology, it is called a "printed" circuit board. PCB is an important electronic component in the electronic industry, serving as the support for electronic components and the carrier for electrical connections of electronic components. PCB has been widely used in the production and manufacturing of electronic products, and the reason why it has been widely used

PCBA features:

PCBA is the abbreviation for Printed Circuit Board+Assembly, which means that PCBA is the entire process of SMT mounting on an empty PCB board, followed by DIP plugins.

Note: SMT and DIP are both ways of integrating parts on a PCB board. The main difference is that SMT does not require drilling holes on the PCB, while DIP requires inserting the PIN pin of the part into the already drilled hole.

SMT (Surface Mounted Technology) surface mounting technology mainly uses a mounting machine to mount some micro and small parts onto a PCB board. Its production process includes PCB board positioning, printing solder paste, mounting machine mounting, passing through a reflow furnace, and manufacturing inspection.

DIP, also known as "plug-in", refers to the insertion of parts on a PCB board. This is a form of plug-in integration used when some parts are larger in size and not suitable for mounting technology. Its main production process includes: pasting adhesive, inserting components, inspection, peak soldering, plate brushing, and production inspection.

Tags: PCBA /PCB /difference /

Prev: Quick Turn PCBA ssembly: Ensuring Speed And Reliability

Next: PCBA processing factory teaches you step by step how to copy the board