Process requirements for DIP plug-in

The process requirements for DIP plug-ins can be summarized as follows:

Preparation before insertion:

Check whether the surface of the electronic components is clean to ensure that there are no unclean objects such as oil stains and paints.

Ensure that the electronic components are oriented correctly, especially for components with directional indication.

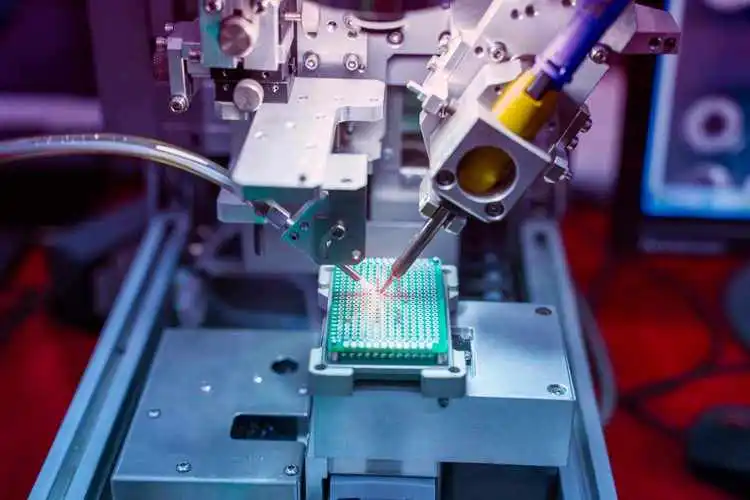

Insertion process:

When inserting, the electronic components must be flat against the PCB, and after the insertion is completed, the electronic components should be guaranteed to be in a flush state, and should not be uneven.

Insertion force should be moderate, to avoid excessive damage to components or PCB damage.

Electronic components can not exceed the edge of the PCB board, need to pay special attention to the height of the electronic components and electronic components between the spacing.

For components with bi-directional direction markers, the plug-in direction must be correct.

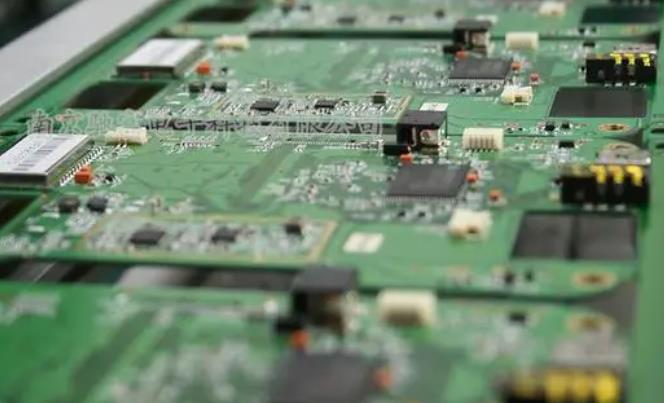

Welding requirements:

After the plug-in is completed, welding is performed through wave soldering. During the wave soldering process, it is necessary to ensure that the solder joints are uniform, no false soldering and no leakage of soldering.

After the welding is completed, the welding quality should be checked to ensure that the welding is firm and reliable.

Subsequent processing:

After the welding is completed, it may be necessary to carry out the operation of cutting the feet to achieve the appropriate size.

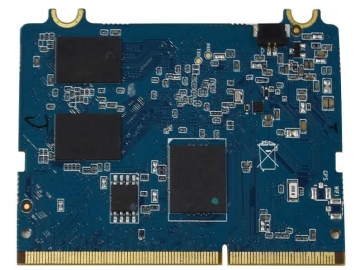

Test the finished PCBA board to ensure normal function and no defects.

If functional defects are detected, repair and retest processing is required until the test is qualified.

Appearance and packaging:

Appearance inspection of the PCB board to ensure that there are no scratches, deformation or other problems on the surface.

Qualified PCBA boards are packaged, common packaging methods include vacuum encapsulation, import and export piping packaging.

Overall quality requirements:

DIP plug-in as an important part of the PCBA process, its quality directly affects the quality of PCBA processing. Therefore, the entire DIP plug-in process needs to be carried out in strict accordance with the requirements to ensure product quality.

Through the strict implementation of the above process requirements, you can ensure the quality and reliability of the DIP plug-in for the subsequent manufacturing of electronic products to provide a solid foundation.

Tags: DIP /DIP_plug-in /

Prev: LED PCB board design and manufacturing process and difficulties

Next: Printed Circuit Board Manufacturer's Introduction to ODM