Printed Circuit Board Manufacturer's Introduction to ODM

ODM, or Original Design Manufacturer, refers to a company that designs and manufactures a product based on a specification provided by another company, who then sells the product under its own brand. In the context of printed circuit boards (PCBs), an ODM manufacturer would design and produce PCBs according to the specific needs and requirements of a client.

Here's a detailed introduction to PCB manufacturers offering ODM services:

Core Capabilities:

- Technical Expertise: Leading PCB ODM manufacturers possess deep technical knowledge and rich experience in product development. They can customize designs based on client needs, covering areas like Battery Management System (BMS) optimization, efficient energy conversion circuit design, and integration of smart features.

- Advanced Technologies: These manufacturers utilize state-of-the-art technologies such as precise control over the charging and discharging process to prolong battery life and advanced inversion techniques to enhance energy conversion efficiency, thereby ensuring high performance and longevity of the products.

Comprehensive Service Chain:

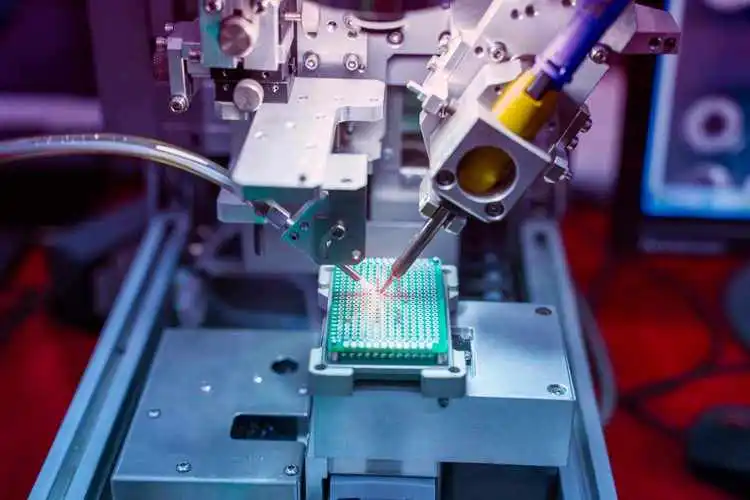

- The ODM solution offered by PCB manufacturers encompasses the entire product development cycle, from conceptual design and component selection to PCB design, SMT patch processing, DIP plug-in welding, complete machine assembly testing, and certification services.

Beyond basic hardware design and production, these manufacturers can also integrate cutting-edge technologies like the Internet of Things (IoT) and cloud computing, imparting smart features like remote control, power monitoring, and fault warning to outdoor power supplies.

Customized Solutions:

- PCB ODM manufacturers excel in providing tailored solutions to meet specific client requirements. This includes designing PCBs for various applications, ranging from consumer electronics to industrial equipment.

- Clients can leverage the manufacturer's expertise to develop products that are optimized for performance, cost, and manufacturability.

Collaborative Approach:

- ODM manufacturers work closely with clients, involving them in key decision-making processes to ensure that the final product aligns with their vision and market positioning.

- Regular communication and feedback loops ensure that any adjustments or improvements can be made swiftly and effectively.

Quality Assurance:

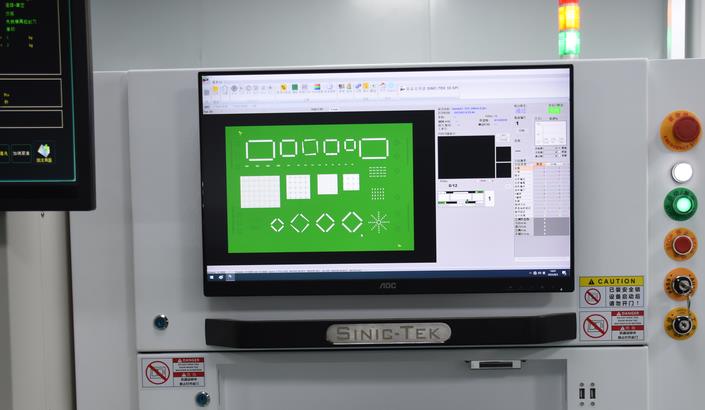

- Quality control is paramount in PCB manufacturing. ODM manufacturers adhere to strict quality standards, conducting rigorous testing and inspections at every stage of the production process.

- This ensures that the delivered products meet or exceed industry standards and client expectations.

PCB manufacturers offering ODM services provide comprehensive, customized solutions that leverage advanced technologies and a collaborative approach to deliver high-quality products tailored to client needs.

Tags: ODM /Printed_Circuit_Board_Manufacturer /

Prev: Process requirements for DIP plug-in

Next: How does the Product Assembly production line ensure product quality?