How does the Product Assembly production line ensure product quality?

The Product Assembly production line ensures product quality through several key measures:

- Quality Control Measures:

- Strict quality control measures are implemented at every stage of the assembly process. This includes inspections and tests to ensure that each component and assembly step meets predefined standards.

- Regular audits and checks are conducted to identify and rectify any deviations from the set quality norms.

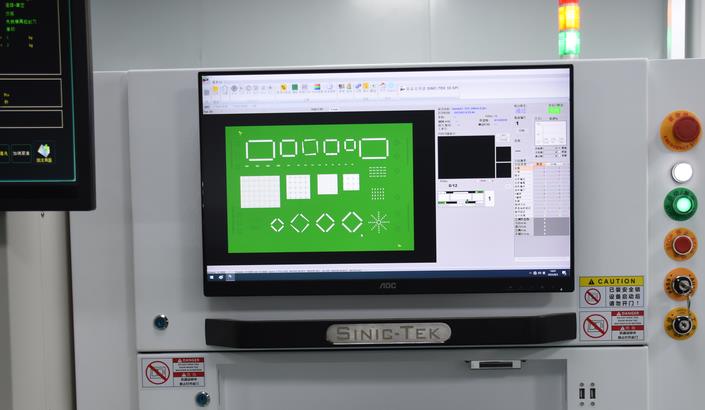

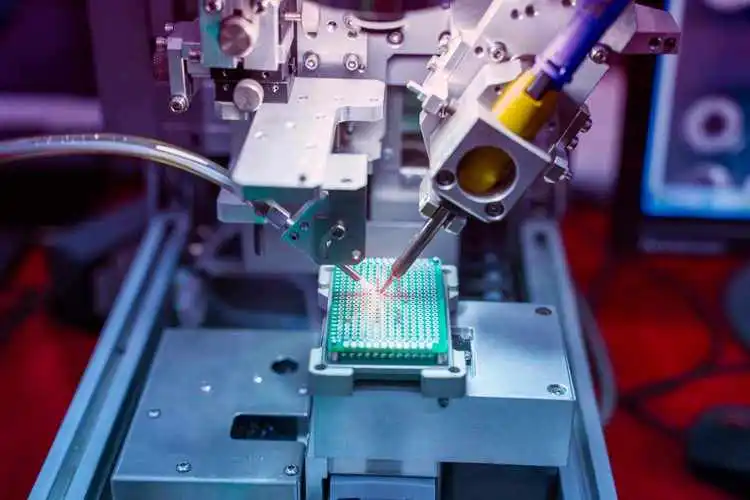

- Automated and Precision Equipment:

- The use of automated and precision equipment reduces human error and ensures consistency in the assembly process.

- Advanced machinery and robots are employed for tasks that require high precision, such as soldering, screwing, and aligning components.

- Training and Skill Development:

- Workers on the assembly line undergo rigorous training to ensure they are skilled and knowledgeable about the assembly process.

Regular refresher courses and skill updates keep the team abreast of the latest assembly techniques and quality standards.

- Standardized Processes:

- Standard operating procedures (SOPs) are followed to maintain uniformity and quality across all products.

- These SOPs detail each step of the assembly process, from component selection to final inspection, ensuring that every product is assembled to the same high standards.

- Continuous Improvement:

- The assembly line incorporates a culture of continuous improvement, where processes are regularly reviewed and optimized to enhance efficiency and quality.

- Feedback loops and regular audits facilitate the identification of areas for improvement and the implementation of corrective actions.

- Use of Quality Materials:

- High-quality raw materials and components are sourced to ensure the durability and reliability of the final product.

- Stringent supplier qualification processes and incoming material inspections guarantee the quality of inputs into the assembly process.

By combining these measures, the Product Assembly production line can consistently deliver high-quality products that meet or exceed customer expectations.

Tags: quality /Product_Assembly /production_line /product /

Prev: Printed Circuit Board Manufacturer's Introduction to ODM

Next: What role does electronic component procurement play in PCB manufacturing?