What role does electronic component procurement play in PCB manufacturing?

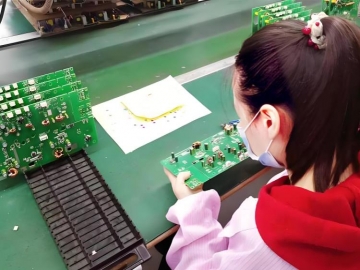

Electronic component procurement plays a crucial role in PCB manufacturing. Here are some key points summarizing its importance:

Supply Chain Efficiency: Efficient procurement of electronic components ensures a smooth and uninterrupted supply chain for PCB manufacturing. This is essential for maintaining production schedules and avoiding delays.

Cost Control: Procurement teams negotiate with suppliers to get the best prices for components, which directly affects the cost of PCB manufacturing. By sourcing components at competitive prices, manufacturers can keep their overall production costs down.

Quality Assurance: Procuring high-quality components is vital for the reliability and performance of the final PCB product. Procurement teams must ensure that components meet specified standards and are sourced from reliable suppliers.

Risk Mitigation: Diversifying component suppliers can help mitigate risks associated with supply chain disruptions. Procurement strategies often involve building relationships with multiple suppliers to ensure a backup plan in case of any supply issues.

Innovation and Technology Advancement: As technology evolves, procurement teams are responsible for staying up-to-date with the latest electronic components. This allows PCB manufacturers to incorporate newer, more efficient components into their products, enhancing performance and competitiveness.

Electronic component procurement is a key function in PCB manufacturing, ensuring efficient supply chains, cost-effective production, high-quality products, risk mitigation, and technological advancement.

Tags: PCB /PCB_manufacturing /electronic_component_procurement /

Prev: How does the Product Assembly production line ensure product quality?

Next: The impact of chaotic PCB layout on soldering reliability