What is one-stop PCB assembly service? What does it include?

The One-stop PCB Assembly Service is a comprehensive electronic circuit board assembly solution that encompasses the entire process, from raw material procurement, PCB manufacturing, component placement, soldering, testing, to final product packaging. This service model aims to provide customers with an efficient, convenient, and all-in-one solution that meets their various needs for circuit board assembly. Here is a detailed breakdown of what this service includes and its characteristics:

Inclusions:

- Raw Material Procurement:

- Sourcing the necessary electronic components, PCB substrates, and other raw materials based on customer designs or requirements.

- PCB Manufacturing:

- Covering the design, fabrication, drilling, exposure, plating, etching, stripping, punching, and electrical testing of PCB boards to ensure they meet design specifications.

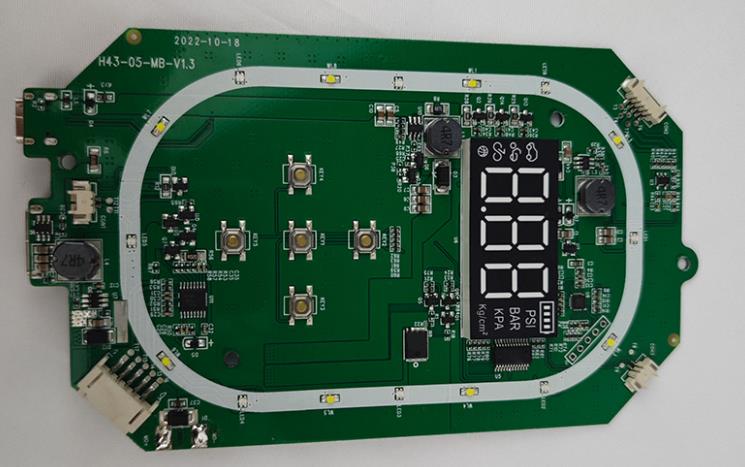

- Component Placement:

- Accurately placing electronic components on PCB boards using Surface Mount Technology (SMT) or Through-Hole Technology (DIP). Supports a wide range of component types, including BGA, CSP, and passive components as small as 0201 sizes.

- Soldering:

- Utilizing water-soluble solder paste or RoHS-compliant lead-free solder to ensure reliable soldering quality that meets environmental standards.

- Testing:

- Offering comprehensive testing services, including Automated Optical Inspection (AOI), In-Circuit Test (ICT), Functional Circuit Test (FCT), and more, to ensure circuit board functionality and performance align with expectations.

- Also capable of advanced testing like Flying Probe Testing and X-ray Inspection to detect potential defects and issues.

- Final Product Packaging:

- Packaging the tested and qualified circuit board products for transportation and storage.

- Additional Value-Added Services:

- Providing PCB layout design, PCBA design, firmware and microcontroller programming, embedded user interface design, and other value-added services.

- Supporting PCBA ODM services, where customers' ideas are turned into PCBA designs and manufacturing.

- Offering prototype and small-batch production services, as well as solutions for large-scale production.

Characteristics:

- Comprehensiveness: Covers the entire process from raw material procurement to final product packaging.

- Efficiency: Reduces customer investment and time costs in intermediate links through a one-stop service.

- Professionalism: Boasts a professional technical team and equipment to ensure quality and efficiency in every step.

- Flexibility: Supports multiple component types and packaging methods to cater to the diverse needs of different customers.

- Value-Added Services: Provides various value-added services to help customers achieve product innovation and upgrades.

The One-stop PCB Assembly Service is an efficient, convenient, and comprehensive solution for electronic circuit board assembly, offering customers a full-chain solution from design to production.

Tags: PCB_assembly /one-stop_PCB_assembly_service /

Prev: Application design requirements for PCB communication product connectors

Next: What is the difference between SMD and SMT? How to choose an SMT factory?