PCB and PCBA for IoT

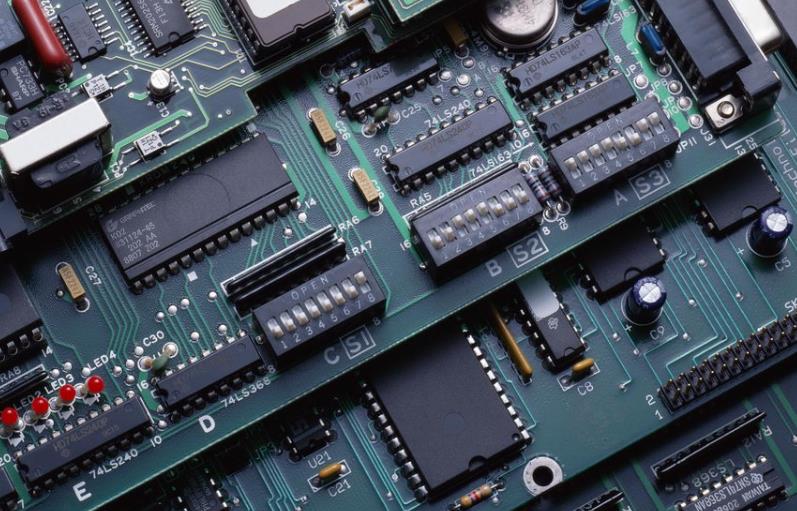

The PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play vital roles in the Internet of Things (IoT). Here's a detailed analysis of their applications in IoT:

PCB Applications in IoT

Fundamental Connectivity:

PCB serves as the core component of IoT devices, facilitating electrical connections and insulation between electronic components. It utilizes an insulating substrate material to separate the conductive copper foil layers, enabling electrical connectivity among various components. It serves as the carrier for the electrical connections of electronic components.

PCBs offer good product consistency and allow for standardized designs, facilitating mechanization and automation in the production process, thus enhancing efficiency.

Accommodating Miniaturization and High-Performance Demands:

As IoT devices evolve towards miniaturization and high performance, PCB technology continues to advance. For instance, HDI (High-Density Interconnect) technology enables more electrical connections within a limited space, catering to complex circuit design needs.

A variety of PCB types, including rigid, flexible, and rigid-flex PCBs, cater to different IoT device requirements. For example, flexible PCBs excel in applications requiring bending or twisting, such as wearable devices.

Supporting High-Speed Data Transmission:

In IoT devices, PCBs need to support high-speed data transmission for real-time communication and data processing. With the advent of communication technologies like 5G, PCB designs must continually optimize to enhance signal transmission speed and stability.

PCBA Applications in IoT

System Integration and Functionality:

PCBA is an electronic assembly formed by processing and assembling PCBs through technologies like SMT (Surface Mount Technology) or THT (Through-Hole Technology). In IoT, PCBA serves as the core part of the system, integrating various sensors, communication modules, processing units, and other key components to achieve device intelligence and interconnectivity.

Sensor Connection and Data Processing:

PCBA connects various sensors (e.g., temperature, humidity, motion sensors) to collect environmental data and transmits it to the cloud or other devices through built-in communication modules (e.g., Wi-Fi, Bluetooth, LoRa, NB-IoT). This data is used for device monitoring and control, enabling automation and intelligent control.

Power Management and Security:

PCBA often includes power management circuits to ensure efficient and stable device operation. Additionally, PCBA involves security considerations such as data encryption, access control, and authentication measures to ensure device and data security.

Customization and Flexibility:

PCBA can be custom-designed for specific IoT applications, including circuit design, layout, and component selection. This customization caters to the unique needs of different IoT devices, enhancing their performance and reliability.

Conclusion

PCB and PCBA play indispensable roles in IoT. PCB acts as the fundamental connectivity platform, enabling electrical connections and insulation between electronic components. Meanwhile, PCBA integrates various key components and sensors to achieve device intelligence and interconnectivity. As IoT technology continues to evolve, PCB and PCBA technologies will also advance and innovate to meet more complex and diverse application requirements.

Prev: How to Reduce the Cost of Flexible PCB Panelized Production?

Next: Low-Volume Or Small Batch PCB Assembly Service

![What is the difference between PCBA and PCB? [Chart Explanation] What is the difference between PCBA and PCB? [Chart Explanation]](https://www.neweiodm.com/uploadfile/2024/0622/thumb_360_270_40266a5f71ff59f.png)