Detailed Explanation of PCBA Custom Development and Ordering Process

The PCBA (Printed Circuit Board Assembly) custom development and ordering process is a complex yet systematic endeavor that encompasses numerous stages, from requirements analysis, design development, raw material procurement, manufacturing, to final testing and delivery. Below is a detailed explanation of this process:

PCBA Custom Development Process

1. Requirements Analysis

Client Communication: Engage in thorough communication with clients to understand their needs, objectives, technical specifications, functional requirements, and performance indicators.

Requirement Definition: Based on the communication, clearly define the specific requirements and specifications for PCBAdevelopment.

2. Circuit Design

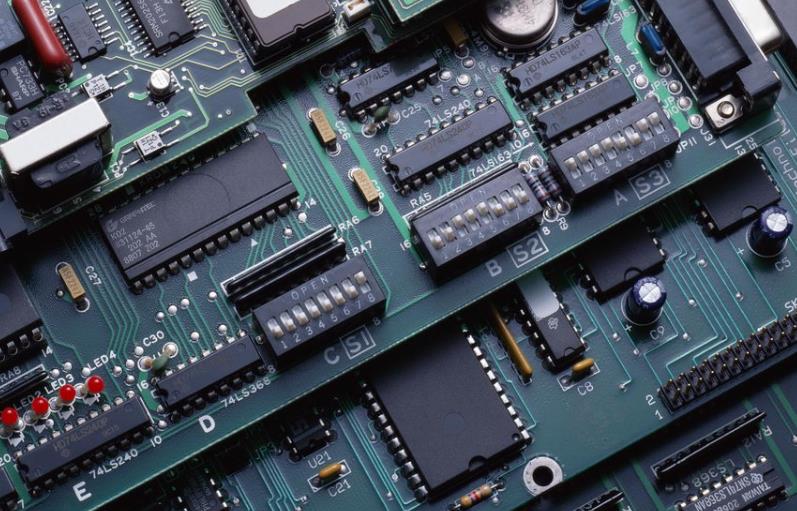

Schematic Design: Design the circuit schematic diagram based on the requirements, determining the connection relationships between components.

Board Layout Design: Optimize the board layout based on the schematic diagram to reduce interference and improve signal quality.

3. Component Selection

Component Selection: Choose suitable components for the circuit design, considering factors such as cost, performance, and availability.

Board Material Selection: Select an appropriate board material, such as phenolic resin, fiberglass, etc., to meet the performance requirements of the circuit board.

4. Prototype Production and Testing

Prototype Production: Fabricate a prototype based on the circuit design.

Functional and Performance Testing: Conduct comprehensive functional and performance testing on the prototype to validate its feasibility and stability.

5. Mass Production Preparation

Design Optimization: Make necessary modifications and optimizations based on prototype test results.

Procurement and Production Preparation: Prepare for mass production by procuring components and setting up production equipment.

6. Mass Production and Testing

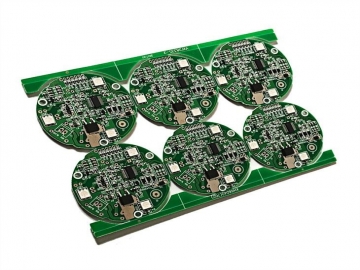

Batch Production: Produce PCBs in large quantities according to the optimized design.

Quality Inspection: Conduct thorough quality inspections on the produced PCBs to ensure they meet quality standards.

7. Quality Control and After-Sales Support

Quality Control System: Establish a quality control system to monitor the entire production process and ensure consistent product quality.

After-Sales Support: Provide necessary after-sales support and services to address any issues encountered by clients during use.

PCBA Ordering Process

1. Login and Registration

Visit Platform: Access the official website or e-commerce platform of the PCBA manufacturer or service provider.

Account Registration: Register an account if not already registered and log in.

2. Select Order Type

Browse Products: Explore PCBA customization services or related products on the platform.

Choose Order Type: Select the appropriate order type based on needs, such as PCBA customization or component procurement.

3. Fill in Order Parameters

Enter Requirements: Fill in detailed parameters for PCBAcustomization as prompted by the platform, such as board size, component list, and special requirements.

Upload Files: If necessary, upload relevant design files or technical documents.

4. Order Verification and Payment

Check Order Details: Carefully review order parameters, prices, and other information to ensure accuracy.

Select Payment Method: Choose a suitable payment method, such as Alipay, WeChat Pay, or bank transfer.

5. Wait for Production and Shipment

Track Production Progress: After payment, monitor the order's production progress through the platform.

Shipment and Logistics: Once production is complete, the manufacturer will ship the order and provide logistics information for tracking.

6. Confirm Receipt and Evaluate

Confirm Receipt: Upon receipt, inspect the products and confirm receipt.

Provide Feedback and Evaluation: Evaluate the products and services, and provide feedback to the manufacturer or service provider.

Notes

Throughout the custom development and ordering process, maintain close communication with the manufacturer or service provider to promptly address any issues that may arise.

Protect intellectual property rights and avoid infringing upon others' patents, trademarks, or other rights.

Verify order information thoroughly before making any payments to ensure accuracy.

By following this process, clients can successfully complete PCBA custom development and ordering, obtaining high-quality PCBA products that meet their specific needs.

Tags: PCBA /Ordering_Process /

Prev: SMT lead-free process requirements and solutions

Next: What does PCB Assembly OEM & ODM Services mean?