How to Improve the Competitiveness of Industrial Manufacturing PCB Services?

To improve the competitiveness of industrial manufacturing PCB services, one can adopt the following strategies:

1. Technological Innovation and Standardization

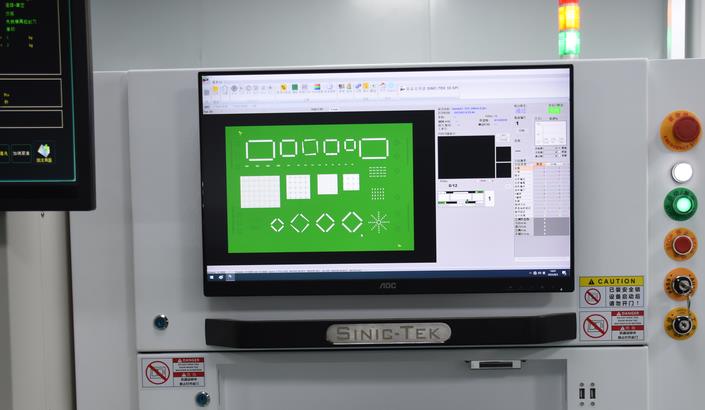

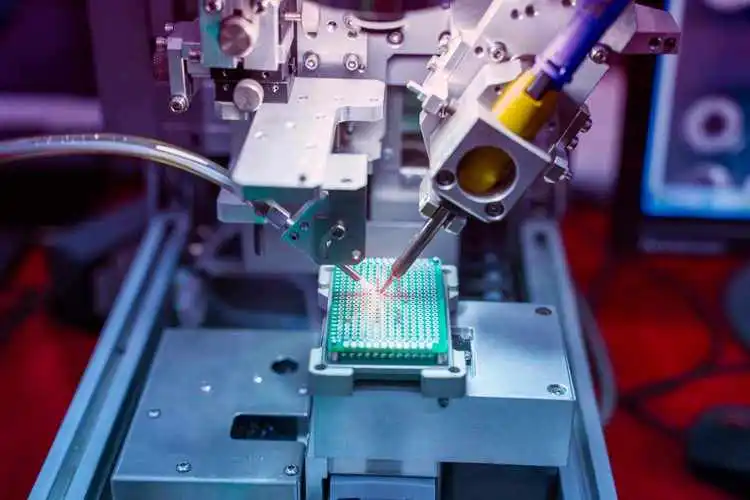

Embrace Technological Innovation: Continuously invest in R&D to introduce new technologies, materials, and processes such as high-precision manufacturing, automated production lines, and intelligent inspection systems. This enhances product quality and production efficiency.Promote Standardization: Drive the standardization of PCB products, including design standards, production processes, and testing criteria. This minimizes variations and waste in production, boosting efficiency and quality.

2. Smart Manufacturing and Digital Transformation

Implement Smart Manufacturing: Establish a smart manufacturing system that automates, digitizes, and intellectualizes production processes. Leverage smart devices and systems like industrial robots, IoT, and big data analytics to increase flexibility and responsiveness.Embrace Digital Transformation: Utilize cloud computing, big data, and AI to optimize business processes, improving decision-making efficiency and operational performance. Build digital platforms to integrate and synergize supply chain, production, and sales.

3. Cost Control and Efficiency Enhancement

Adopt Lean Manufacturing: Implement lean principles to eliminate waste, streamline processes, and maximize equipment utilization, thereby reducing costs and improving productivity. Strengthen employee training and skill development.Optimize Supply Chain Management: Foster long-term partnerships with suppliers for timely supply and cost control of raw materials and components. Enhance inventory management to minimize stockpiles and capital tie-ups.

4. Quality Management and Customer Service

Strengthen Quality Management: Establish a robust quality management system that rigorously controls every aspect from raw material sourcing to final product inspection. Strengthen quality monitoring to ensure compliance with customer requirements and industry standards.Elevate Customer Service: Enhance customer service across pre-sales consultation, mid-sales support, and post-sales maintenance. Implement rapid response mechanisms to promptly address customer concerns, fostering satisfaction and loyalty.

5. Environmental Protection and Sustainable Development

Pursue Green Manufacturing: Adopt eco-friendly practices, utilizing green materials and processes to minimize pollution and waste during production. Enhance wastewater, exhaust gas, and other waste treatment and recycling for resource conservation and emission reduction.Commit to Sustainable Development: Stay abreast of industry trends and market demands, crafting long-term development plans and strategies. Strengthen R&D and talent cultivation to support sustainable growth.

6. International Strategy and Brand Building

Pursue International Expansion: Actively explore international markets, engaging in global competition and cooperation. Understand regional laws, market needs, and cultural nuances to tailor marketing and service strategies.Strengthen Brand Building: Intensify brand promotion and development, enhancing brand recognition and reputation. Leverage industry expos, new product launches, and branding campaigns to amplify brand appeal and influence.

By integrating these strategies, industrial manufacturing PCB services can significantly enhance their competitiveness, positioning themselves at the forefront of the industry and ensuring sustainable growth.

Tags: PCB /PCB_Services /Industrial_Manufacturing /

Prev: What does PCB Assembly OEM & ODM Services mean?

Next: 纽维实业祝愿祖国繁荣昌盛祝大家国庆快乐