The Advantages of Wave Soldering: Precision and Efficiency in PCB Assembly

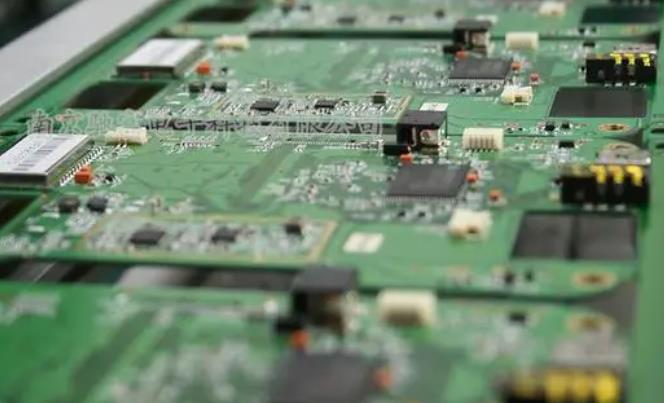

In the fast-paced world of electronics manufacturing, achieving high-quality solder joints with precision and efficiency is crucial. Among the various soldering techniques, wave soldering has emerged as one of the most reliable methods for assembling printed circuit boards (PCBs). Whether you're manufacturing consumer electronics, automotive parts, or medical devices, wave soldering offers a range of advantages that can streamline your production process and enhance the overall quality of your products.

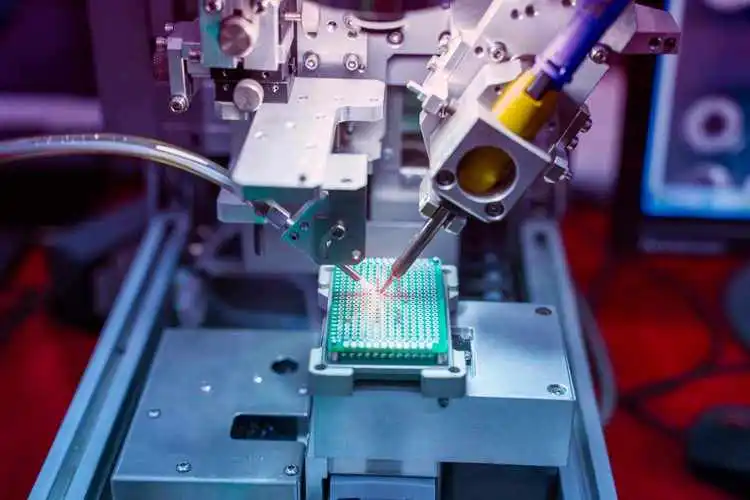

What is Wave Soldering?

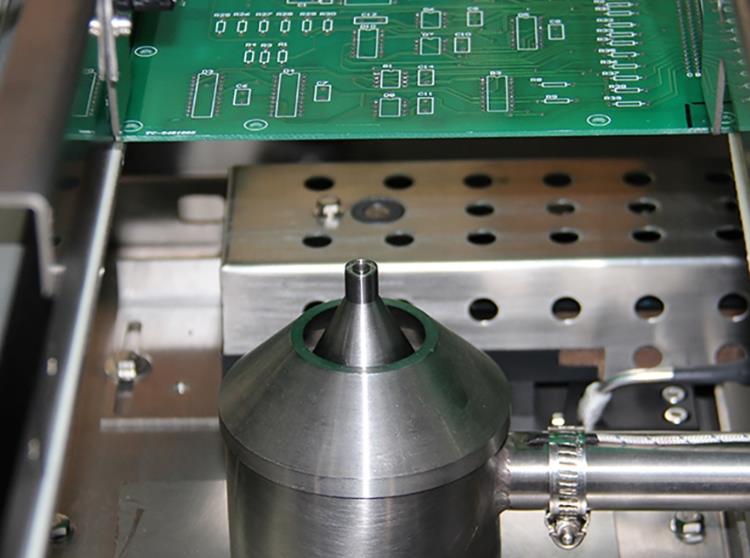

Wave soldering is an automated soldering process used to solder electronic components to a PCB, typically through-hole components. In this process, the PCB is passed over a wave of molten solder, ensuring that the solder wets the pins of the components and forms strong, reliable solder joints. The method is efficient and effective for large-scale production, particularly when dealing with high-volume PCB assemblies.

Key Advantages of Wave Soldering

1、High Efficiency and Speed

One of the main advantages of wave soldering is its speed. Unlike manual soldering methods, wave soldering can handle multiple PCBs at once, making it ideal for high-volume manufacturing. The automation of the process not only reduces labor costs but also significantly increases throughput, allowing manufacturers to meet tight production deadlines without sacrificing quality.

2、Consistency and Precision

Wave soldering provides a high degree of consistency in the soldering process. Since the soldering is done through a controlled wave of molten solder, each PCB receives uniform soldering across all the joints. This level of consistency is especially important in industries such as medical devices or automotive electronics, where reliability and precision are non-negotiable.

3、Reduced Human Error

In traditional hand soldering, there is always the risk of human error, such as inconsistent solder application or insufficient heating. Wave soldering, being an automated process, minimizes these errors and ensures that every PCB is soldered to the same standard. This not only improves the quality of the final product but also reduces the likelihood of rework or defects.

4、Cost-Effective for High-Volume Production

For large-scale production runs, wave soldering is incredibly cost-effective. The automation of the process reduces the need for manual labor, which can drive down production costs. Additionally, the ability to solder multiple PCBs simultaneously means that manufacturers can achieve economies of scale, resulting in cost savings for both the business and the customer.

5、Ideal for Through-Hole Components

While surface-mount technology (SMT) has gained popularity in recent years, many products still rely on through-hole components for added durability and reliability. Wave soldering is particularly effective for soldering through-hole components, as the molten solder easily flows through the holes and creates strong, long-lasting connections.

6、Minimal Flux Residue

Wave soldering typically produces minimal flux residue compared to other methods. This is an advantage because excessive flux residue can lead to corrosion and electrical short circuits over time. With wave soldering, the controlled environment and precise application of solder help minimize the amount of residue left on the board, leading to higher reliability and fewer post-soldering cleaning steps.

7、Versatility and Adaptability

Wave soldering is highly adaptable and can be used for a wide variety of PCB sizes and designs. Whether you're working with a complex multi-layer PCB or a simple single-sided board, wave soldering can handle it all. This versatility makes it a popular choice for manufacturers across many different industries, from consumer electronics to aerospace.

Conclusion

Wave soldering continues to be an essential tool in modern PCB assembly, offering a range of advantages that help manufacturers produce high-quality, reliable products at scale. With its efficiency, precision, and cost-effectiveness, wave soldering stands out as an ideal solution for high-volume production runs, especially when working with through-hole components. As the demand for quality electronics continues to rise, wave soldering will remain a vital technique in ensuring that products meet the rigorous standards of the modern market.

Tags: PCBA /PCB Assembly /Wave Soldering /

Prev: PCB Aging Test: Ensuring Long-Term Reliability and Performance

Next: SMD vs SMT: Understanding the Key Differences in Electronics Assembly