How to Choose the Right PCBA Supplier? Key Factors Explained

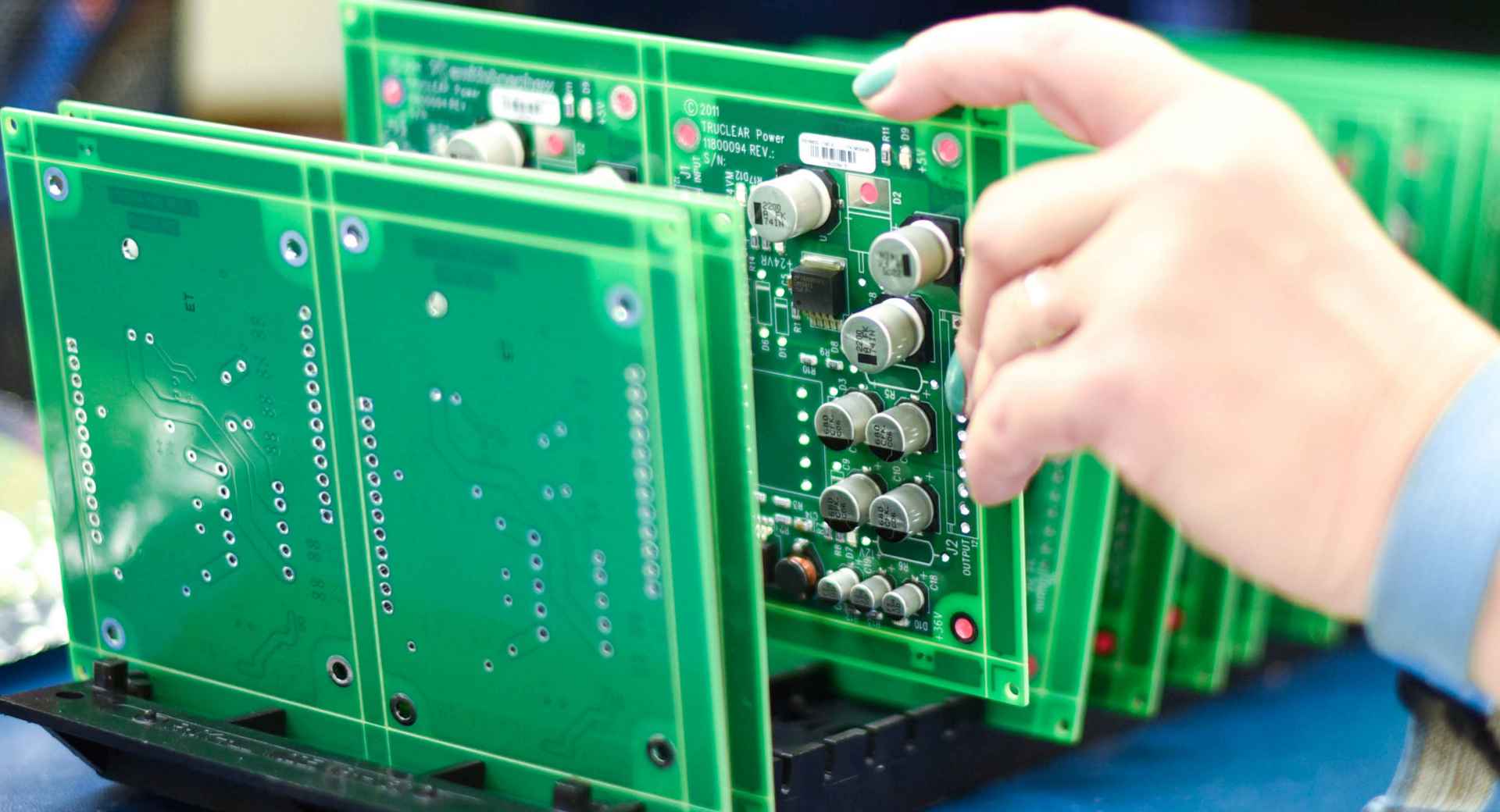

In the electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) is the core of product performance, directly affecting the stability and lifespan of end devices. However, many customers feel confused when selecting a PCBA supplier and are unsure how to determine whether a supplier is reliable. Today, we will analyze the key factors to consider when choosing a PCBA supplier, helping you find the best partner for your needs.

1. Does the Supplier Have Complete Production Certifications?

The first thing to consider when choosing a PCBA supplier is whether the factory has the necessary industry certifications, such as ISO9001 Quality Management System Certification, BSCI Certification, and compliance with China 3C, EU CE, US FCC, and RoHS standards. These certifications demonstrate the supplier’s compliance with quality control, environmental protection, and product safety regulations. If a supplier lacks these basic certifications, it is best to look elsewhere.

2. Is the SMT Assembly Process Advanced?

SMT (Surface Mount Technology) is a crucial process in PCBA manufacturing, directly affecting soldering quality, reliability, and production efficiency. A high-quality PCBA supplier should be equipped with high-precision SMT production lines, AOI optical inspection equipment, and SPI solder paste inspection machines to ensure the stability of each circuit board. This is especially important for high-density, multi-layer boards and high-speed signal transmission applications.

3. Can They Provide One-Stop OEM/ODM Services?

For many companies, finding a PCBA supplier is not just about purchasing circuit board assembly services but also about getting full-process support from design solutions, PCBA prototyping, and small-batch trial production to mass production. A strong PCBA supplier should offer R&D design, BOM optimization, PCBA assembly, testing, and final packaging and shipping, helping clients accelerate time to market and enhance their competitiveness.

4. Are PCBA Testing Procedures Rigorous?

Reliability testing is critical to ensuring long-term stable operation of PCBA products. A high-quality supplier should conduct ICT (In-Circuit Testing), FCT (Functional Testing), Aging Tests, High-Low Temperature Cycle Tests, and X-Ray Inspections to ensure that the products function properly in various environments. If a supplier lacks a well-established testing system, PCBA quality cannot be guaranteed, increasing the risk of product failures and returns.

5. Is the Delivery Capability Stable?

One common issue businesses face with PCBA suppliers is unstable delivery schedules. A reliable supplier should have a comprehensive supply chain management system, intelligent production scheduling, and sufficient raw material inventory to ensure on-time delivery of orders, preventing delays due to material shortages or production capacity limitations.

Choose the Right PCBA Supplier to Gain a Competitive Edge

PCBA is the core component of electronic products, and selecting a supplier with extensive experience, complete certifications, advanced equipment, strict testing processes, and stable delivery capabilities can significantly improve product quality, reduce defect rates, and lower after-sales maintenance costs.

If you are looking for a high-quality PCBA manufacturer, feel free to contact us. Our factory covers 13,000 square meters, equipped with 4 SMT production lines, 4 assembly lines, and 2 packaging lines, supported by over 30 professional R&D engineers. We offer one-stop PCBA customization and production services to help bring your products to market faster.

Tags: PCBA /PCBA Supplie /

Prev: Wave Soldering vs. Reflow Soldering: Choosing the Right Method for Your PCB Assembly

Next: No more...