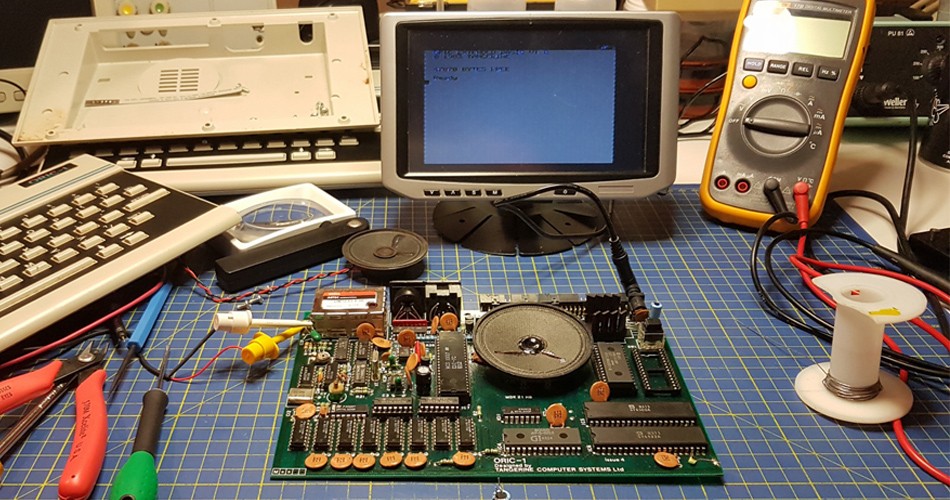

Why do the components on the PCBA board fail for no reason?

Sometimes the component failure on the PCBA board is due to a "sudden failure" of the component, and sometimes there is pressure but it is not obvious, so it feels like the failure is for no reason, but we have not found the reason. "Sudden failure" of a device is a cumulative decay effect resulting from physical or chemical changes. Everyone knows that electrolytic capacitors and certain types of film capacitors are "mortal" because their dielectric undergoes chemical reactions under the combined action of trace impurities (oxygen, etc.) and electrical pressure.

As integrated circuit structures become smaller and smaller following Moore's Law, there is an increased risk that dopant migration at normal operating temperatures will cause devices to fail in decades rather than centuries. In addition, magnetostriction-induced fatigue causes mechanical fatigue in inductors, a well-known effect. Some types of resistive materials oxidize slowly in air, and the oxidation rate increases when the air becomes more humid. Likewise, no one expects batteries to last forever.

Therefore, when selecting a device, it is necessary to understand its structure and possible age-related failure mechanisms; these mechanisms may affect the device even when it is used under ideal conditions. This article will not discuss failure mechanisms in detail, but most reputable manufacturers are concerned with the aging of their products and are generally familiar with operating life and potential failure mechanisms. Many system manufacturers provide information on the safe operating life of their products and their limiting mechanisms.

However, under proper operating conditions, most electronic devices have a life expectancy of decades or more, but some will still fail prematurely. The reason is often the pressure of not being noticed. Anyone designing electronics for use in a marine environment will consider salt spray and humidity—and rightfully so, because they're terrible! In fact, many electronic devices can be subject to chemical challenges that are less scary but can still cause harm.

Human (and animal) breath contains moisture and is slightly acidic. Kitchens and other domestic environments contain a variety of mildly corrosive fumes such as bleach, disinfectants, various cooking fumes, oils and alcohols. All of these fumes are not very harmful, but we should not take it for granted that we The circuit will be "safe for life" under the condition of being well protected. Designers must consider the environmental challenges a circuit will encounter and, where economically feasible, design to minimize any potential hazards.

Electrostatic damage (ESD) is a stress mechanism for which warnings are most common but often ignored. When PCBs are produced, factories take adequate measures to eliminate ESD during the manufacturing process. However, after delivery, many PCBs are used in systems that do not have adequate protection against ESD caused by general operations. It is not difficult to provide adequate protection, but it will increase the cost a little, so it is often ignored. (Probably because of the bad economy). Evaluating what ESD protection system electronics require under the most extreme conditions of normal use and considering how to implement it should be part of any design.

Another factor is overvoltage. It is rare that a semiconductor or capacitor is required to survive a significant overvoltage, but it is common for large value resistors to encounter voltages well above the absolute maximum listed in the data sheet. The problem is: while its resistance is high enough not to get hot, tiny arcs can occur inside it, causing it to slowly drift out of spec and eventually short out. Large wirewound resistors typically have breakdown voltages of hundreds of volts, so this problem was less common in the past, but today small surface mount resistors are widely used and their breakdown voltages may be less than 30 V, making them quite susceptible to overvoltage.

High currents can also cause problems. Everyone is familiar with the common fuse—it's a length of wire that heats up and blows if too much current flows through it, preventing power shorts and other similar problems. However, if there are extremely high current densities in a very small conductor, the conductor may not get very hot, but it may still fail eventually.

The cause is something called electromigration3 (sometimes also called ion migration). That is, the momentum transfer between conducting electrons and diffusing metal atoms causes the ions in the conductor to gradually move, causing a material transport effect. This causes thin conductors carrying large DC currents to become thinner and thinner over time, eventually failing.

But some parts can fail like a fuse, that is, blow, such as wires or conductive traces on a semiconductor chip. A common reason for this phenomenon due to large currents is that the capacitor charging current is too large. Consider a 1 µF capacitor with an ESR of 1 Ω. If it is connected to a 110 V, 60 Hz AC source, approximately 41 mA of AC current will flow through it. But if you connect to AC power when the voltage is at its maximum (110√2 = 155.6 V), only the ESR will limit the current and the peak current will reach 155.6 A, which although it lasts less than 1 μs, is enough to damage many small signals Semiconductor device.

Repeated surges can damage the capacitor itself, especially electrolytic capacitors. This is a particularly common failure mechanism in inexpensive, low-voltage switching power supplies ("wall power adapters") used to charge small electronic devices. If inserted at the wrong time of an AC cycle, the rectifier and capacitor can carry a very large inrush current, which may eventually damage the device if this happens multiple times. Using a small resistor in series with the rectifier can limit this inrush current and minimize the problem.

If we're lucky, an ESD or overvoltage/overcurrent event damages the device immediately, making it easy to know what the problem is. But more often, stress-induced damage causes the device to fail, long after the stress that caused the failure in the first place has disappeared. Diagnosing the cause of such failures is difficult, if not impossible.

No matter what circuit is designed, it is necessary to consider the operating life and failure mechanisms of the devices used, and whether there are any potential problems or stressors that could cause damage to the device under the most extreme conditions of use allowed. Any such issues should be considered and, if possible, minimized in the final design.

Tags: PCBA /PCBA_board /components /

Prev: The difference between laser welding and reflow soldering in PCBA processing