What is PCB SMT reflow soldering process?

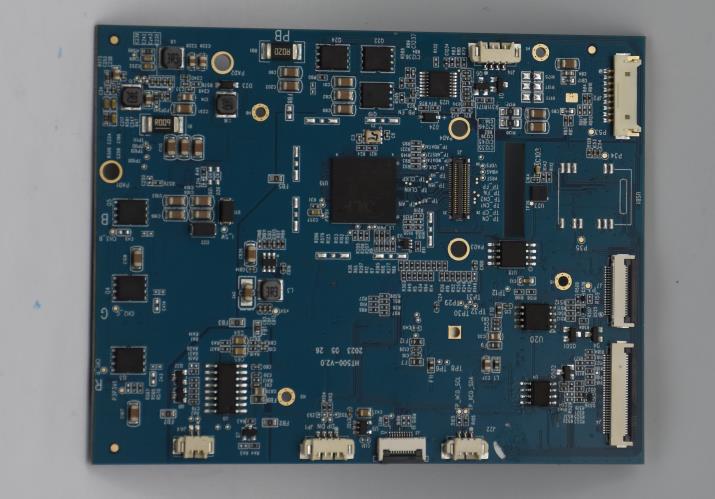

SMT Reflow Soldering Process refers to a technology that realizes the mechanical and electrical connection between the terminals or pins of surface-mounted components and the solder pads on the printed circuit board (PCB) by reheating and remelting the solder paste that has been pre-dispensed onto the solder pads. Here is a breakdown of the key steps involved in the SMT Reflow Soldering Process:

Preparation: Initially, a layer of solder paste, typically a mixture of small metal particles and flux, is applied to the PCB. This solder paste melts at high temperatures to form the solder joint.

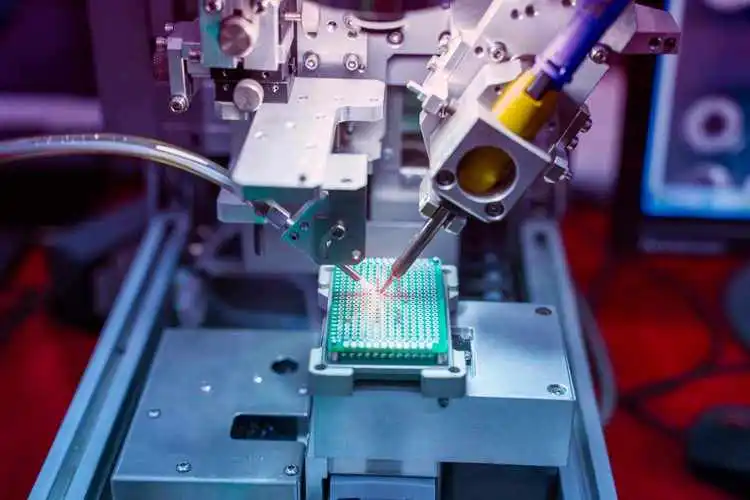

Component Placement: The SMT components to be soldered are precisely positioned on the PCB surface, often using automated equipment.

Preheating: The PCB and the components are then preheated using hot air or steam flow to bring the entire assembly to the desired temperature for soldering. This gradual increase in temperature avoids thermal shock that could damage the SMT components.

Soldering: Once the preheating reaches the appropriate temperature, the PCB enters the soldering zone. In this zone, the hot air or steam continues to heat up, melting the solder paste and forming a connection between the SMT components and the solder pads on the PCB. The surface tension of the molten solder paste ensures that it wets the solder pads and component leads properly.

Cooling and Solidification: After soldering, the PCB and the soldering area gradually cool down. During this process, the solder paste solidifies, forming a reliable solder joint.

The SMT Reflow Soldering Process relies on precise temperature control and automated equipment to ensure the reliable connection between SMT components and the PCB. It is an essential process in the manufacturing of electronic devices, ensuring the electrical performance and reliability of the final product.

Prev: Why do PCBA circuit boards sometimes require a dispensing process?