Reflow soldering and wave soldering process principles, application scenarios, advantages and disadvantages

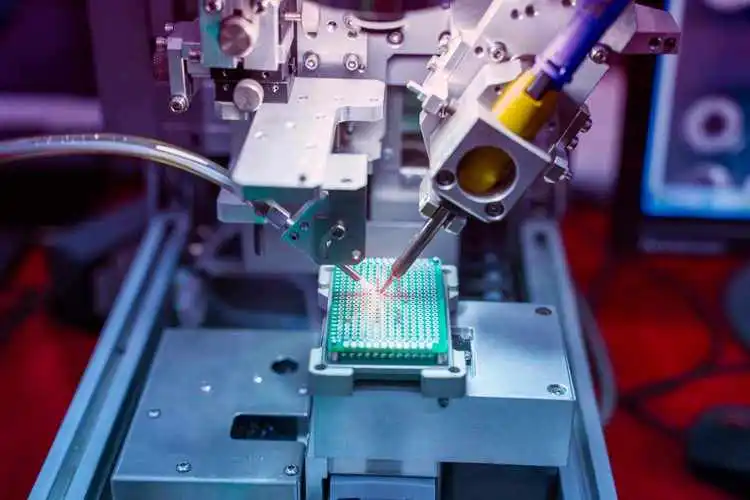

Reflow Soldering: Reflow soldering is a process where pre-dispensed solder paste on the printed circuit board (PCB) is reheated and remelted to achieve a mechanical and electrical connection between the terminals or pins of surface-mounted components and the solder pads on the PCB.

Wave Soldering: Wave soldering is a process where molten solder is pumped to form a wave or "peak" at the surface of a solder pot. PCBs with pre-inserted components are then passed over the wave, allowing the solder to contact and bond the component leads to the PCB pads.

Comparison of reflow soldering and wave soldering

Process principle

Reflow Soldering: Utilizes a paste-like solder that is dispensed onto the PCB pads before components are placed. Heating the PCB melts the solder paste, creating a bond.

Wave Soldering: Forms a wave of molten solder. PCBs with inserted components are passed through the wave, contacting the solder and forming a bond.

Application Scenarios

Reflow Soldering: Mainly used for surface-mounted components (SMT) with shorter pins or leads. It offers high precision and is suitable for dense and complex PCB layouts.

Wave Soldering: Typically used for through-hole components (THT) with longer pins or leads. It is faster and more suitable for mass production.

Advantages and Disadvantages

Reflow Soldering: Advantages include high precision, good soldering quality, and suitability for high-density PCBs. However, it requires precise temperature control and has a higher equipment cost.

Wave Soldering: Advantages are faster soldering speed, higher production efficiency, and lower equipment cost. However, it may be less suitable for high-density PCBs and sensitive components.

Both reflow soldering and wave soldering have their respective advantages and disadvantages. The choice depends on the specific production requirements, PCB type, and component characteristics. For example, SMT components would be best suited for reflow soldering, while THT components would benefit more from wave soldering. Ultimately, the best approach is to Select the process that meets the requirements while also balancing cost and efficiency.

Tags: wave_soldering /

Prev: What is PCB SMT reflow soldering process?

Next: PCB assembly factory answers for you: What are the components of a circuit board?

![What is the difference between PCBA and PCB? [Chart Explanation] What is the difference between PCBA and PCB? [Chart Explanation]](https://www.neweiodm.com/uploadfile/2024/0622/thumb_360_270_40266a5f71ff59f.png)