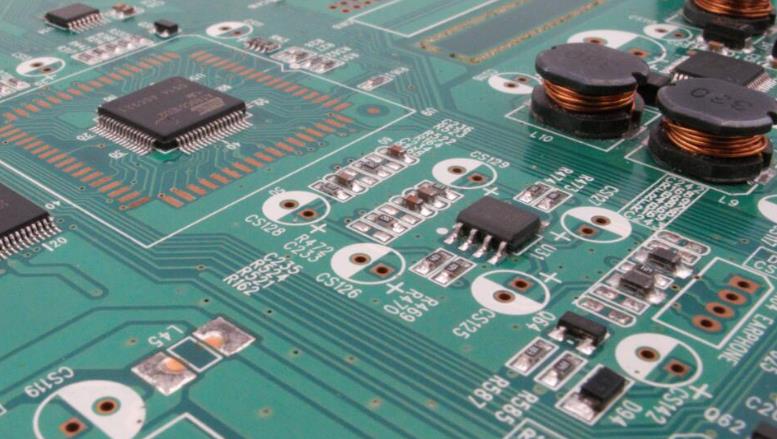

Why is the PCB circuit board green?

The PCB circuit boards are often green due to several reasons:

Cost Efficiency:

Green ink has been widely used for a long time and is relatively inexpensive in the market. Large-scale production using green ink offers a more economical solution for manufacturers.

For example, green ink from major ink manufacturers like Nanya is generally priced around 80 yuan/KG, which is cost-effective compared to other colors.

Ease of Imaging:

Green PCBs are easier to image during the manufacturing process as the green color is more permeable to developer solutions, making it simpler to remove unwanted parts.

Visual Effect and Identification:

The green PCB background helps enhance the visual contrast of brightly colored metal pads and markings, making the board easier to identify and maintain.

During SMT (Surface Mount Technology) processes like solder paste application, component placement, and final AOI (Automated Optical Inspection) verification, the green background provides better optical positioning and calibration.

Less Harmful to Eyes:

Prolonged observation of circuit boards under bright light can cause eye strain, but green color is less harmful to the eyes compared to other colors.

Environmental Protection and Safety:

Green PCBs are generally safe and environmentally friendly as they do not release toxic gases when used in high-temperature environments.

Good Confidentiality:

The common green color of PCBs makes it difficult for others to guess or imitate the specific design of the circuit board, enhancing confidentiality.

Long History of Use:

Since the mid-to-late 20th century, the industry started paying attention to the color of PCBs, and green PCBs have been widely adopted due to their stability and cost-effectiveness, forming a long history of use.

Technical Characteristics:

Some technical documents indicate that green ink can achieve higher design precision and better characteristics, such as hole filling properties, which are crucial in some high-precision PCB designs.

The reasons for the prevalence of green PCBs involve cost, imaging, visual effects, environmental protection, confidentiality, history, and technical characteristics. However, with technological advancements and diversifying demands, PCB colors are also becoming more diverse, allowing customization based on customer needs.

Tags: PCB_circuit_board /green /

Prev: PCB assembly factory answers for you: What are the components of a circuit board?

Next: The difference between PCBA processing and assembly?