PCBA testing principle

Connect the test points on the PCBA board through the FCT test stand, forming a complete path to connect the computer and burner, and upload the MCU program. The MCU program will capture the user's input actions (such as long pressing the switch for 3 seconds), and through calculation, control the on/off of the adjacent circuit (such as flashing LED) or drive the motor to rotate. By observing the voltage and current values between test points on the FCT test stand, and verifying whether these input and output actions match the design, the entire PCBA board can be tested.

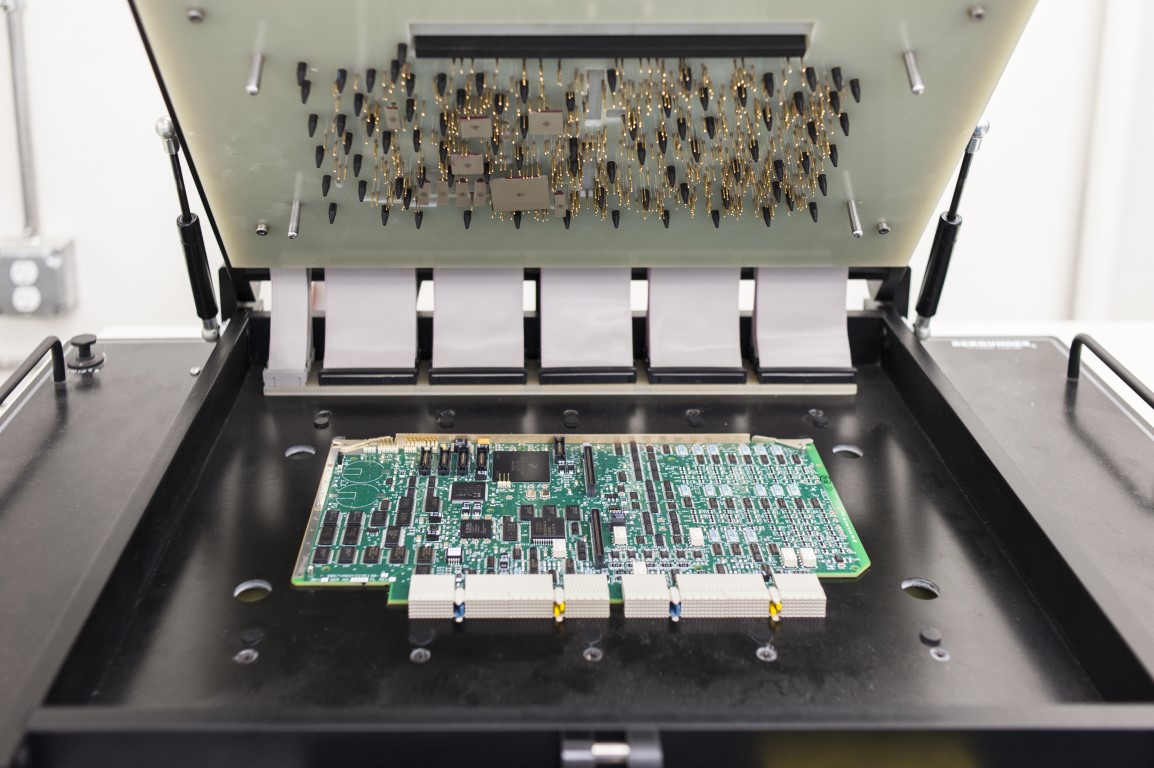

PCBA test stand

Testing is necessary for the processing of large quantities of PCBA boards, and corresponding test fixtures are usually issued to assist in efficient completion. The principle of the test stand is to connect the test pin to the test point of the PCB board, and when powered on, obtain key data such as voltage and current in the circuit, and display them on the display screen of the test stand to achieve rapid detection. When customers design PCB boards, engineers will consider their testing plans, reserve PCB testing points, and provide professional testing documents or plans to the manufacturer. Our company can produce PCBA testing racks by ourselves (equipped with engraving machines and testing rack assembly engineers).

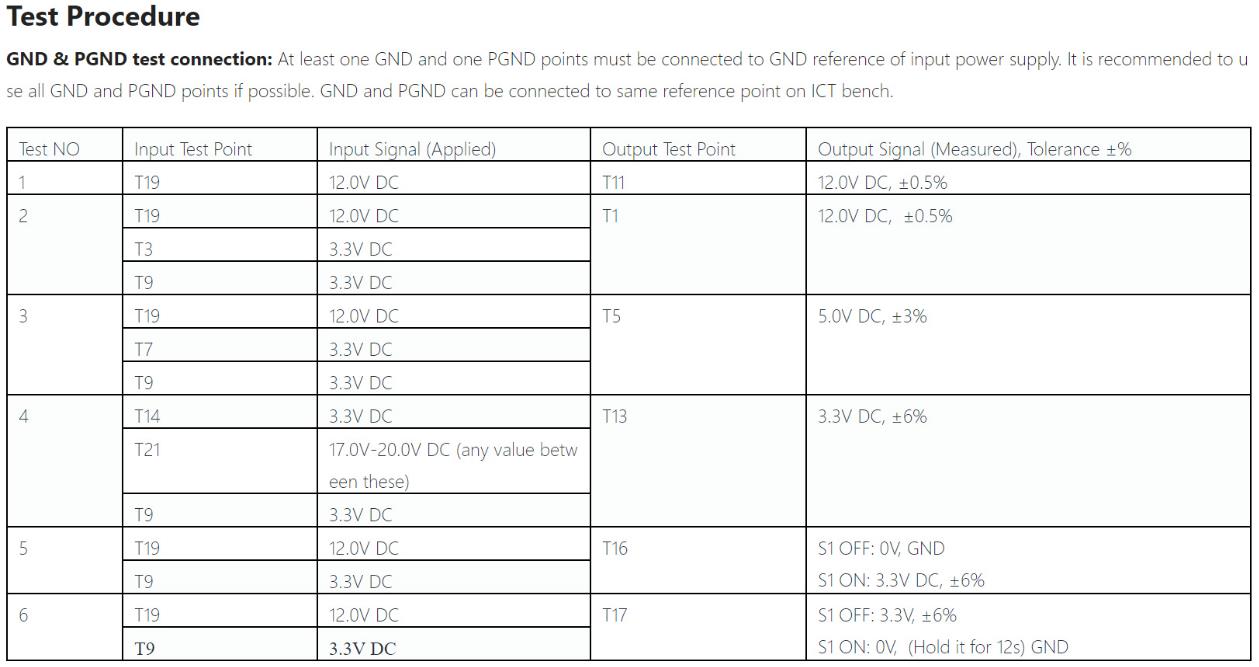

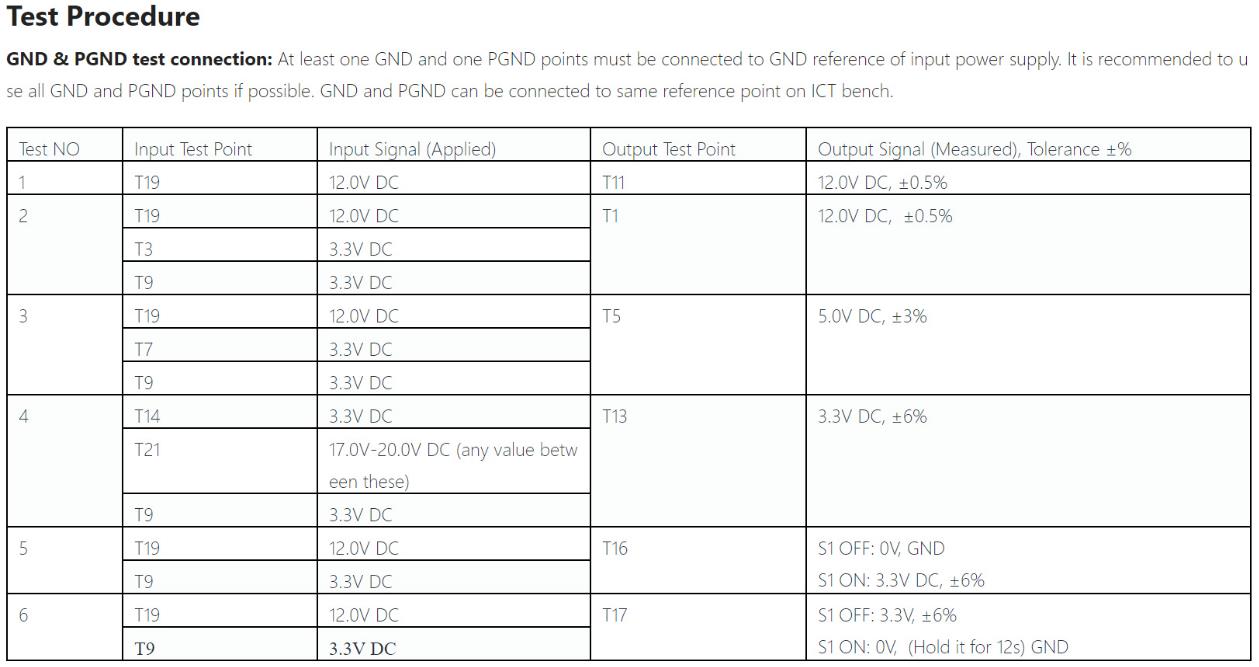

Example: PCBA testing plan for a foreign customer

The types of PCBA testing are divided into the following:

ICT (In Circuit Test): mainly used to detect the voltage/current data of the test points after the PCB circuit board is powered on, without involving functional buttons or input/output testing.

FCT (Functional Test) testing: First, the written microcontroller (MCU) program needs to be burned into the program IC through a burner (such as ST Link, JTAG) to achieve corresponding functional testing. For example, after pressing the button, the LED lights up; Press both buttons simultaneously to restore factory settings, and so on. Of course, whether all functional tests can be carried out must be based on the premise that the PCB soldering is OK and the circuit is conductive, otherwise it cannot be achieved.

Burn In Test: Conduct long-term and periodic simulation of user input and output on PCBA boards that have been programmed and FCT passed, in order to test their durability and welding reliability. In special circumstances, it is also necessary to expose the PCBA board to specific temperature and humidity environments.

PCBA testing is an essential and important link in the entire PCBA manufacturing supply chain, controlling quality from the final data results. In standardized design and manufacturing management, PCBA testing must be considered and implemented.