Introduction to Enterprise Services

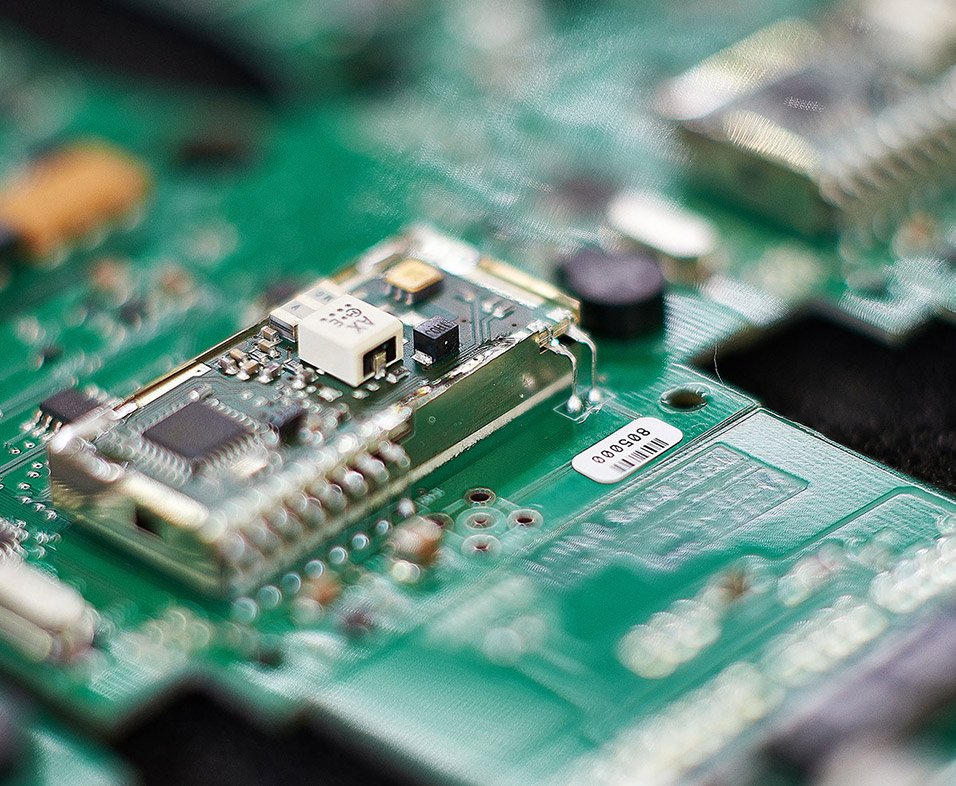

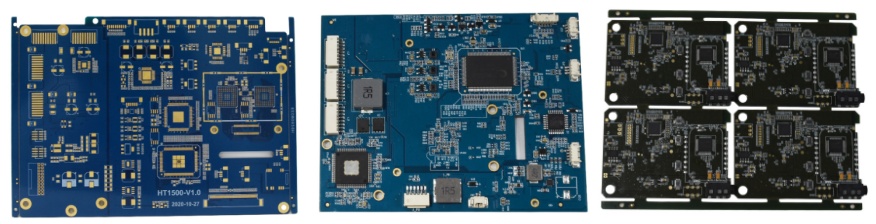

Newei Industrial focuses on PCBA, SMT patch, DIP plug-in, post-soldering, testing, spraying, assembly packaging processing/ OEM, ODM, and integrated electronic component procurement, serving the global electronics industry.

NeweiIndustrial has experienced engineering team, excellent managers and electronic components procurement team, serving numerous domestic and foreign customers in various industries such as automotive electronics, medical electronics, power communication, industrial automation, and smart home, etc. The products involve industrial control, industrial, consumer, network communications, medical, sensor modules, traffic control, automotive, smart home, self-service terminals, digital, computer peripherals and other industry sectors.

Provide high-quality, professional, fast, and convenient SMT patch processing, DIP plug-in, post-solder testing, complete machine assembly packaging processing, and OEM\ODM processing services for domestic and foreign high-tech enterprises, research institutions, universities, integrated circuit manufacturers, and consumer solution companies. Able to provide customers with a complete one-stop service from PCBA, SMT patch, DIP, testing, coating, assembly, packaging, complete machine assembly research and development, and electronic material procurement.

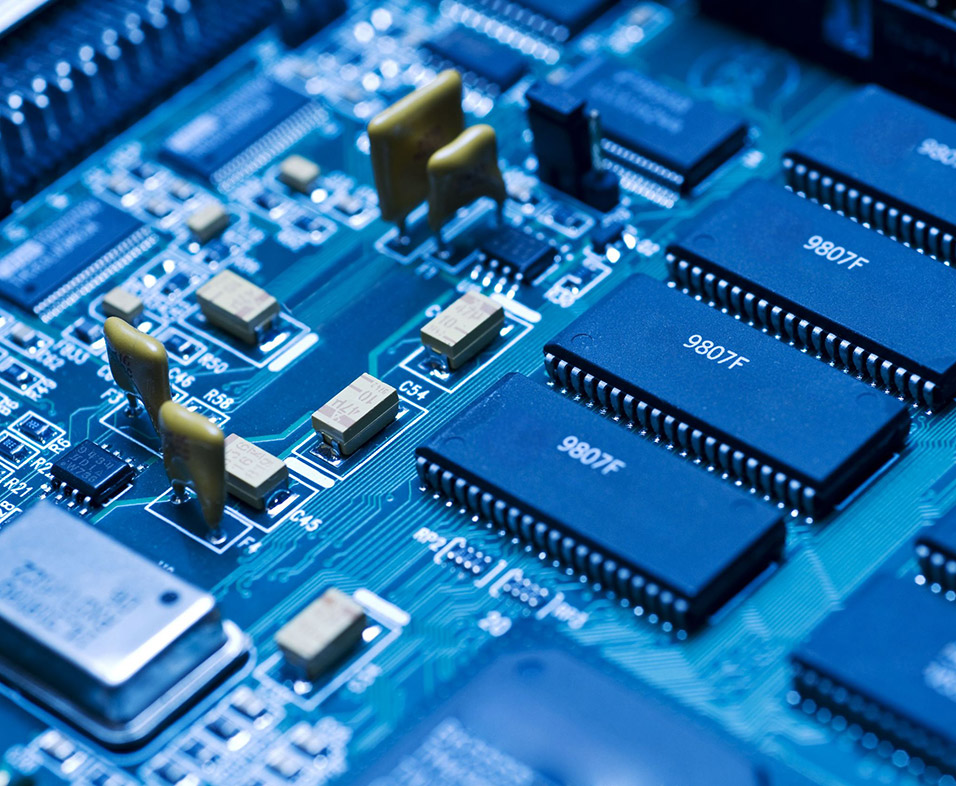

The company has passed ISO 14001, ISO 9001, IATF 16949 system certification, has multiple SMT patch, DIP plug-in, post-solder, testing, coating, assembly production lines, equipped with new imported YAMAHAYSM20R high-speed patch machine, fully automatic solder paste printer, ten temperature zone reflow oven, wave soldering and other high-end equipment, and equipped with online SAKI AOI, XRAY, SITAC online 3D AOI, BGA rework station and other equipment.

Fully air-conditioned dust-free and anti-static operation workshop, SMT patch daily capacity: 10 million points/day, DIP plug-in capacity: 500,000 points/day, post-soldering: 80,000 points/day, testing: 10,000 PCBs/day, assembly, packaging, complete machine monthly capacity: 400,000-600,000 pcs/month. All products undergo strict quality control testing equipment, pass through multiple layers of "testing processes" to ensure quality, strictly adhere to ISO 14001, ISO 9001 system standards, providing reliable guarantee for product quality.

Service support

Sales one-on-one follow-up service

Sales staff receive customers one-on-one,

Answer customer questions,

Follow up the status of customer orders.

Ensure that customers know the production status at the first time.

Engineering project follow-up service

Project engineers follow up the whole project of the customer's current batch of production.

Before production: repeated confirmation of the information.

During production: random inspection of the products in production to ensure compliance with the requirements of the production data.

After production: Technical support engineers provide relevant technical support and follow up on the logistics and transportation status to ensure the products reach the customers.

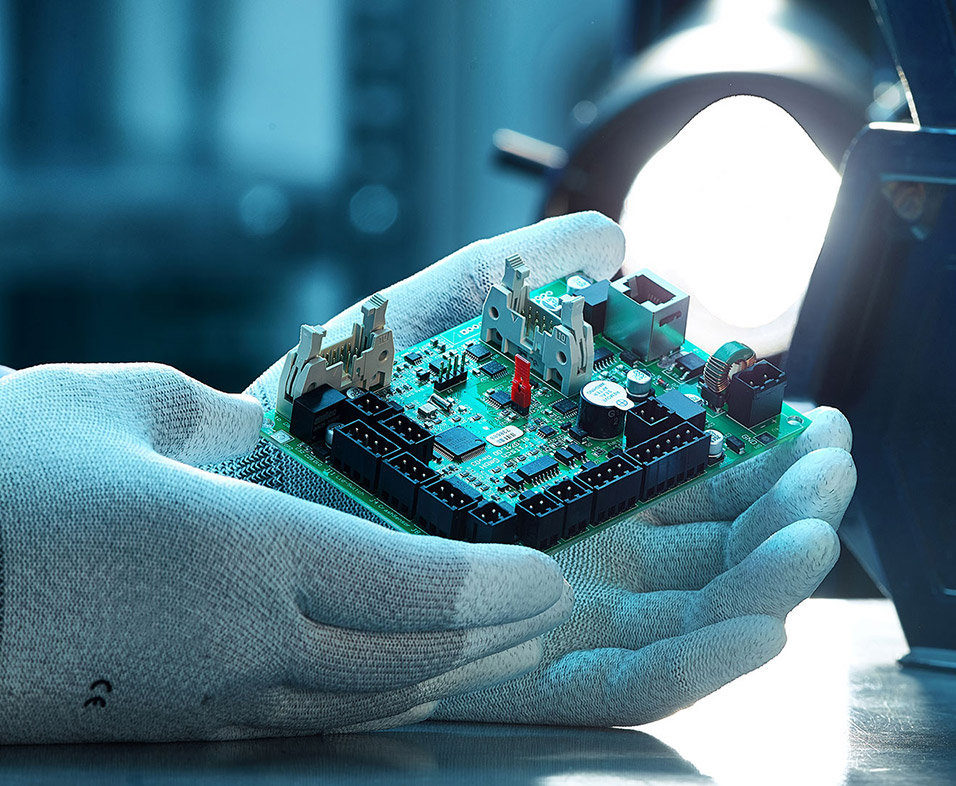

Quality assurance service

1. We guarantee that the purchased materials are procured according to customer requirements and ensure they are genuine original products.

2. We guarantee that if the products we produce encounter quality issues, we will provide free repairs without material costs.

3. All cooperating customers are entitled to free technical support from the company for life, as well as the right to obtain quotations for free.

We provide BOM Bill of Materials Procurement Service

We have a team of electronic components procurement with over 10 years of experience, strategic partnerships with hundreds of global original factories and distributors, ensuring genuine products, support for loose parts shipping, accurate manual quoting, and direct procurement from original factories and distributors.

Supporting 'one-stop' BOM procurement service, solving your multi-point purchasing troubles, supporting various types, small batch electronic component supply services, solving your prototype production, new product development, project order additional emergency replenishment issues. We have established an annual SQE audit mechanism internally, evaluating all suppliers, to ensure the continuous supply and quality capabilities of electronic components.

After-sales Service

If there are defects or damages during delivery, repair and rework services will be provided. Communication comes first.

PCB Fabrication

PCB Fabrication PCB Assembly

PCB Assembly Stencil

Stencil Quick Turn PCB & PCBA

Quick Turn PCB & PCBA Managing BOM

Managing BOM On-time Shipping

On-time Shipping